The role of steam generator in the production process of chemical fiber rope netting

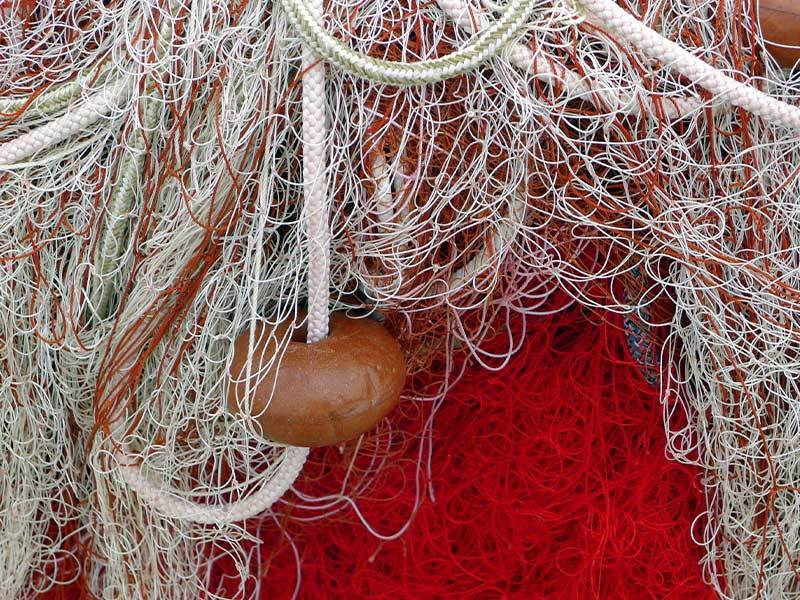

Chemical fiber rope mesh is made of nylon, polyamide, polyester and other chemical fibers, processed by wire mesh machinery. Its use is extremely wide, in the field of construction, construction safety nets can effectively prevent people and objects from falling, high-rise buildings often with the help of it to achieve fully enclosed construction; agriculture, sunshade nets can be used for plant shading, to create a suitable environment for growth; fisheries fishing, various types of chemical fiber mesh to help harvesting; industrial filtration, petroleum chemical industry, printing and other industries can not be separated from the chemical fiber rope mesh, used for sieving, filtration, and other operations. Steam generators play an indispensable role in the production process of chemical fiber rope mesh. First of all, in the raw material processing stage, the steam generator produces high temperature steam can be used to preheat the fiber raw materials. Different chemical fibers have specific requirements for processing temperature, the steam generator can produce steam in 28 seconds, the heat of the steam quickly raise the temperature of the raw material, so that it reaches a suitable state for subsequent processing, for the subsequent drawing, weaving and other processes to lay a good foundation.

Steam generators play an indispensable role in the production process of chemical fiber rope mesh. First of all, in the raw material processing stage, the steam generator produces high temperature steam can be used to preheat the fiber raw materials. Different chemical fibers have specific requirements for processing temperature, the steam generator can produce steam in 28 seconds, the heat of the steam quickly raise the temperature of the raw material, so that it reaches a suitable state for subsequent processing, for the subsequent drawing, weaving and other processes to lay a good foundation. Secondly, in the wire mesh forming process, a steam generator is essential for some of the chemical fiber wire mesh that requires a heat lamination process. Steam generator steam can realize “micro-superheated” steam continuous and stable output, to ensure that the temperature is constant in the appropriate range during the thermal bonding process. Stable temperature can ensure that the nodes of the rope mesh are firm, avoiding the nodes not being firm due to temperature fluctuations, improving the overall quality and durability of the rope mesh, and making the made rope mesh more resilient to meet the needs of different scenarios.

Secondly, in the wire mesh forming process, a steam generator is essential for some of the chemical fiber wire mesh that requires a heat lamination process. Steam generator steam can realize “micro-superheated” steam continuous and stable output, to ensure that the temperature is constant in the appropriate range during the thermal bonding process. Stable temperature can ensure that the nodes of the rope mesh are firm, avoiding the nodes not being firm due to temperature fluctuations, improving the overall quality and durability of the rope mesh, and making the made rope mesh more resilient to meet the needs of different scenarios. Furthermore, the steam generator helps to improve production efficiency. Its 28 seconds of steam, with a thermal efficiency of 101.21%, not only shortens the preheating and processing time of raw materials, but also realizes the efficient operation of the production line, reduces the fuel consumption of the enterprise and lowers the production cost. Moreover, the continuous supply of steam can maintain the continuity of production, reduce the downtime caused by unstable heating of equipment, ensure the rhythm of production, reduce production costs and improve the economic efficiency of enterprises.

Furthermore, the steam generator helps to improve production efficiency. Its 28 seconds of steam, with a thermal efficiency of 101.21%, not only shortens the preheating and processing time of raw materials, but also realizes the efficient operation of the production line, reduces the fuel consumption of the enterprise and lowers the production cost. Moreover, the continuous supply of steam can maintain the continuity of production, reduce the downtime caused by unstable heating of equipment, ensure the rhythm of production, reduce production costs and improve the economic efficiency of enterprises. Finally, the steam generated by the steam generator can be used to dry the chemical fiber mesh during the post-processing of the product. The freshly produced rope mesh may contain certain moisture, the micro-superheated steam generated by the steam generator can reach 99.07% dryness, accelerating the evaporation of moisture through the heat of the steam, so that the rope mesh reaches the appropriate dryness, preventing mold and mildew due to moisture, affecting the quality, and prolonging the service life of the rope mesh.

Finally, the steam generated by the steam generator can be used to dry the chemical fiber mesh during the post-processing of the product. The freshly produced rope mesh may contain certain moisture, the micro-superheated steam generated by the steam generator can reach 99.07% dryness, accelerating the evaporation of moisture through the heat of the steam, so that the rope mesh reaches the appropriate dryness, preventing mold and mildew due to moisture, affecting the quality, and prolonging the service life of the rope mesh.

Related News

The role of steam generator in the production process of chemical fiber rope netting

Finally, the steam generated by the steam generator can be used to dry the chemical fiber mesh during the post-processing of the product. The freshly produced rope mesh may contain certain moisture, the micro-superheated steam generated by the steam generator can reach 99.07% dryness, accelerating the evaporation of moisture through the heat of the steam, so that the rope mesh reaches the appropriate dryness, preventing mold and mildew due to moisture, affecting the quality, and prolonging the service life of the rope mesh.

What can a gas steam generator do during the production of chili sticks?

It can be said that the gas steam generator by virtue of its own advantages throughout the production of chili, each step is inseparable from its help, a strong guarantee of chili's deliciousness and quality, and promote the chili industry continues to grow and develop.

What can steam generators be used for?

As industrial technology continues to advance, steam generators are also developing in the direction of greater energy efficiency and intelligence. In the future, steam generators will continue to empower industries to promote a green and sustainable industrial development model while improving production efficiency and ensuring product quality.

The role of steam generators in the production of nutrient soils

These properties allow steam generators to play a key role in soil sterilization. High-temperature steam can quickly penetrate the soil layer and efficiently kill soil pathogenic bacteria, such as Fusarium and Fusarium oxysporum, as well as insect eggs and weed seeds. Steam penetrates up to 30 - 50 centimeters into the soil, which is effective in deep sterilization and helps to solve the problem of continuous crop failure.

What are the features of a Palerton steam generator

In addition, one of the outstanding features of Palerton's steam generators is the exemption from inspection, which greatly simplifies the preliminary procedures for the use of the equipment and the subsequent regulatory process, saving a great deal of time and effort for the enterprise, so that it can focus more on the core production business.

What are the advantages of a steam generator over a boiler?

Whether it is the subversion of the traditional speed of response, or nearly extreme energy conversion efficiency, or watertight intelligent safety protection, have made it become the enterprise cost reduction and efficiency, breakthroughs in production capacity bottlenecks of the core weapon. When the limitations of the traditional boiler has gradually become a shackle on the development of enterprises, gas steam generator is more agile adaptability, more powerful productivity and more reliable safety, drive industrial production to a higher form of evolution, for the modern industry to inject a steady stream of surging kinetic energy.