PRODUCT CENTER

Palerton Group holding company limited established in 2007.Focus on the high-end steam boiler research and development,production and sales as the core business.

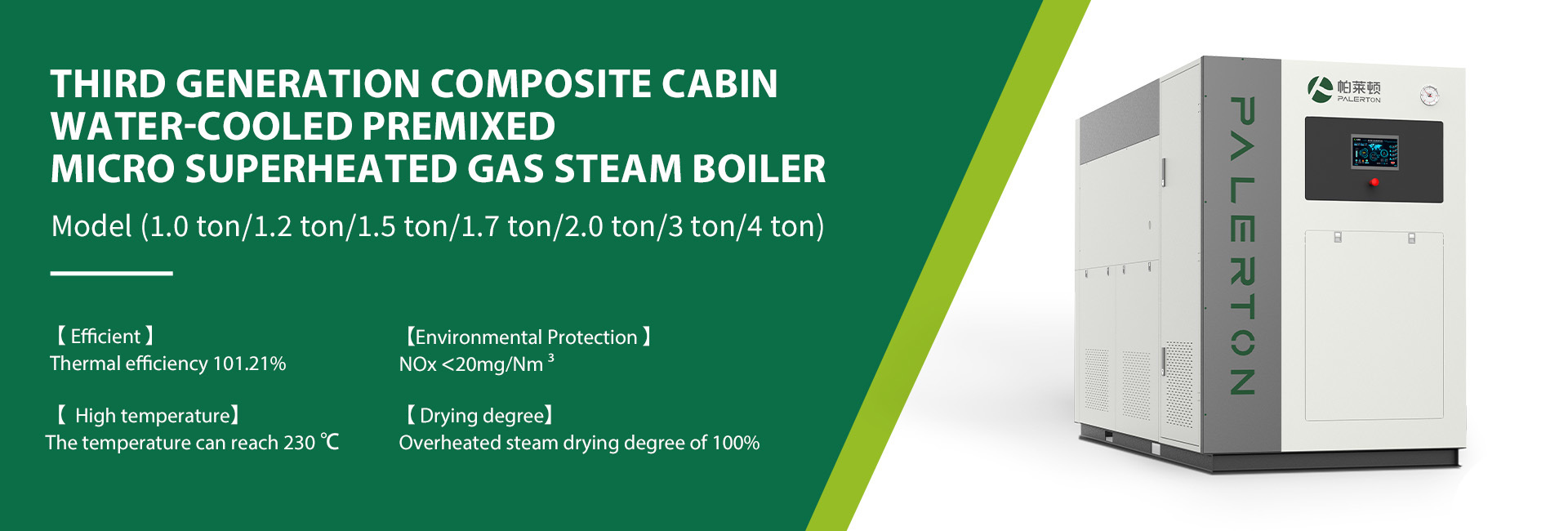

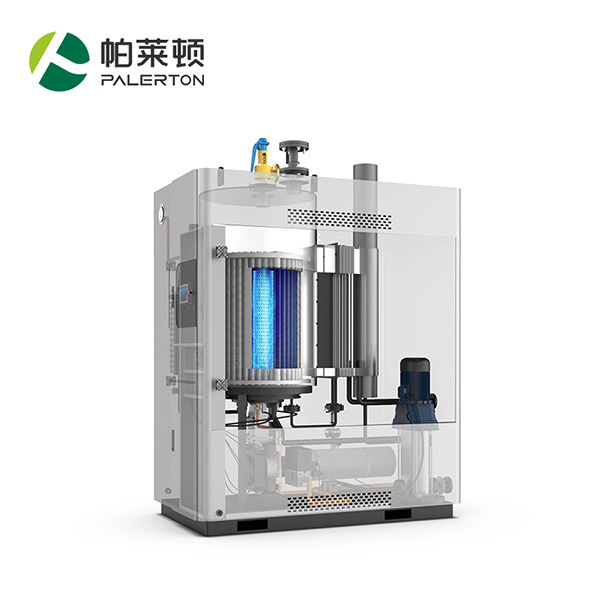

Composite chamber micro-overheated gas steam boiler 1.2ton

Composite chamber micro-overheated gas steam boiler 1.2ton

More +Composite chamber micro-overheated gas steam boiler 1ton

Composite chamber micro-overheated gas steam boiler 1ton

More +WNS New Industrial Horizontal Fire Tube Boilers Restaurant Hotels Manufacturing Plant Automatic Low Pressure Steam Output

More +Palerton Electric Heating Steam Boiler 72kw Electric Steam Generator

PALERTON Electric Heating steam boiler 12KW Electric steam generator

More +Palerton Gas Steam Generator 0.2ton Natural Gas Steam Boiler

PALERTON Gas steam generator 0.2Ton Natural gas steam boiler

More +Palerton Gas Steam Generator 0.3ton Natural Gas Steam Boiler

PALERTON Gas steam generator 0.3Ton Natural gas steam boiler

More +ABOUT

Palerton Group holding company limited established in 2007.Focus on the high-end steam boiler research and development,production and sales as the core business.One-stop steam energy solution provider.The group has nine major subsidiares and offices in 32 major cities across the country. Palerton self-developed the FPTS cross-chamber full premixed surface combustion, High thermal efficiency 100.25% and Nox emissions reaching world leading level,Fully meeting China’s strict ultra-low nitrogen emission requirement.

MORECASE CENTER

Palerton Group holding company limited established in 2007.Focus on the high-end steam boiler research and development,production and sales as the core business.

-

Public area

Hotels, saunas, venues applications

-

Processing and maintenance

Cement maintenance, washing and ironing, bridge and road maintenance

-

chemical process

Metal crafts, rubber processing, industrial processing (cleaning line)

-

Food field

Food processing, wine distillation, beverages

-

Biochemical engineering

Biopharmaceuticals, medical disinfection, experimental research

-

textile

textile, ironing

NEWS CENTER

Palerton is long term commitment to providing high-quality products and services for enterprises.Creating environmentally friendly ,efficient and energy-saving production methods.Enable million of enterprises to enjoy higher quality steam energy services.

What are the advantages of using 100% dry slightly superheated steam during down processing?

2026-01-16

From raw materials to finished products, 100% micro-superheated steam technology safeguards the quality of down jackets, enabling businesses to achieve a win-win situation in terms of cost and efficiency. It protects health needs with residue-free high-temperature sterilization and reduces the burden on businesses with its high energy efficiency. This winter, when you put on a lightweight and warm down jacket, you may be receiving this thoughtful protection from steam technology.

2026-01-15

From routine disinfection of ward linens to emergency supplies of surgical drapes, steam generators, with their consistently online and stable performance, ensure the thorough disinfection of textiles. On the front lines of healthcare infection control, they may work silently, but they safeguard the safety of medical staff and patients with every wisp of high-temperature steam. This reliability hidden within the disinfection process is a crucial cornerstone for the safe operation of hospitals.

when purchasing a steam generator : How many have you fallen for?

2026-01-12

Therefore, it is recommended to accurately match production capacity with manufacturing process requirements, examine the quality of core components, and choose a brand that can provide on-site maintenance and rapid response after-sales service. Only by avoiding these pitfalls can steam generators truly become a production aid rather than an operational burden.

The National Day express delivery package contained a steam generator.

2026-01-09

It can be said that the steam generator is the core power source for the efficient production of corrugated paper. Under the pressure of the National Day express delivery peak, its stable heating and reliable performance give corrugated paper the confidence to bear and protect it, building a solid first line of defense for the safe transportation of massive amounts of parcels.