What industries are the Composite Cabin Micro-superheated Steam Generator (Class D) used in?

In the biopharmaceutical industry, the production of pharmaceuticals has extremely stringent environmental and technological requirements. The composite chamber micro-superheated steam generator (Class D) can produce stable micro-superheated steam, which is used to sterilize equipment and pipelines, effectively killing bacteria, viruses and other microorganisms, ensuring that the drug production process is not contaminated, and guaranteeing the quality and safety of drugs. In the feed processing industry, it can be used in the high-temperature conditioning of feed. Micro-superheated steam can rapidly raise the temperature of feed materials, promote starch paste, protein denaturation, improve feed palatability and digestibility, while killing harmful microorganisms in the raw materials to extend the shelf life of feed.

In the feed processing industry, it can be used in the high-temperature conditioning of feed. Micro-superheated steam can rapidly raise the temperature of feed materials, promote starch paste, protein denaturation, improve feed palatability and digestibility, while killing harmful microorganisms in the raw materials to extend the shelf life of feed. In the laundry industry, the micro-superheated steam produced by this equipment can be used for high temperature ironing and deep cleaning of clothes. The high temperature steam effectively removes stubborn stains and odors, and at the same time acts as a sterilizer and disinfectant, meeting the needs of high-end clothing care.

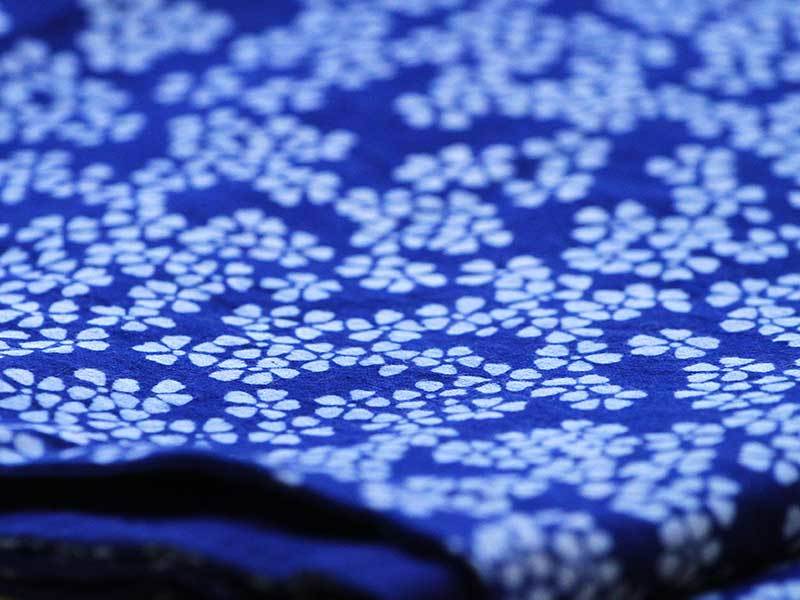

In the laundry industry, the micro-superheated steam produced by this equipment can be used for high temperature ironing and deep cleaning of clothes. The high temperature steam effectively removes stubborn stains and odors, and at the same time acts as a sterilizer and disinfectant, meeting the needs of high-end clothing care. In the textile industry, micro-superheated steam performs well in the pretreatment, dyeing and finishing processes of fabrics. Pre-treatment can make the fabric fiber fully expanded, improve the uniformity of dyeing; finishing link can give the fabric a soft, flat texture.

In the textile industry, micro-superheated steam performs well in the pretreatment, dyeing and finishing processes of fabrics. Pre-treatment can make the fabric fiber fully expanded, improve the uniformity of dyeing; finishing link can give the fabric a soft, flat texture. In the printing and dyeing industry, it can provide a stable heat source for the printing and dyeing process, ensure precise control of the temperature of the dye liquor, enhance the dyeing rate and color fastness of the dyes, and make the printing and dyeing products colorful and long-lasting. In the packaging industry, the steam generated by it is used for heat-shrinking treatment of packaging materials to achieve efficient and beautiful packaging effect.

In the printing and dyeing industry, it can provide a stable heat source for the printing and dyeing process, ensure precise control of the temperature of the dye liquor, enhance the dyeing rate and color fastness of the dyes, and make the printing and dyeing products colorful and long-lasting. In the packaging industry, the steam generated by it is used for heat-shrinking treatment of packaging materials to achieve efficient and beautiful packaging effect. The composite chamber micro-superheated steam generator (Class D) has become a reliable partner for quality improvement and efficiency enhancement in a number of industries due to its stable and efficient performance. In the future, as the production process requirements of various industries continue to improve, it will continue to expand the application boundaries by virtue of the advantages of energy saving and environmental protection, as well as a variety of functions, and bring new breakthroughs and development for more fields.

The composite chamber micro-superheated steam generator (Class D) has become a reliable partner for quality improvement and efficiency enhancement in a number of industries due to its stable and efficient performance. In the future, as the production process requirements of various industries continue to improve, it will continue to expand the application boundaries by virtue of the advantages of energy saving and environmental protection, as well as a variety of functions, and bring new breakthroughs and development for more fields.

Related News

What role can steam generators play when involved in rubber production?

From raw material processing to finished product output, steam generators are deeply integrated into the whole process of rubber production, building a solid foundation for product quality with accurate temperature control and stable energy supply, and enhancing the market competitiveness of enterprises with energy-efficient advantages. With the accelerated process of industrial intelligence, steam generators will also continue to iterate and upgrade, with a smarter, more environmentally friendly and more efficient posture, continue to empower the rubber industry, helping the industry to move towards green, refined, high-end, and blossom in more areas of the unique value and charm of rubber products.

The Role of Steam Generators in Feed Production

steam generator, with its various important roles, has become the key equipment to ensure product quality and production efficiency in feed production, and has opened a new chapter in the high-quality development of the feed industry.

The role of steam generators in the production of concentrated syrups

With stable heat supply and precise parameter control, the steam generator runs through the whole process of concentrated syrup production, which strongly guarantees the supply of raw materials for the summer cold drink market, so that consumers can enjoy cool and sweet drinks to their heart's content.

What are the safety features of the Composite Cabin Micro-superheated Steam Generator (Class D)?

Composite chamber micro-superheated steam generator (Class D) from the beginning of the design, built a set of perfect safety and security system, from the qualification, quality control, performance testing, intelligent control to the use of guidance, to build a set of strict and perfect safety and security system, all-round, dead-end guarding the operation of the equipment, to provide users with safe, reliable and reliable, trustworthy use of the experience.

What industries are the Composite Cabin Micro-superheated Steam Generator (Class D) used in?

The composite chamber micro-superheated steam generator (Class D) has become a reliable partner for quality improvement and efficiency enhancement in a number of industries due to its stable and efficient performance. In the future, as the production process requirements of various industries continue to improve, it will continue to expand the application boundaries by virtue of the advantages of energy saving and environmental protection, as well as a variety of functions, and bring new breakthroughs and development for more fields.

Application and advantages of steam generator in sterilization process

Steam generators play an important role in the sterilization process due to their quick start-up, flexibility, convenience and excellent steam quality, and have become an ideal choice for many industries that have strict requirements on sterilization effect and efficiency.