Can the composite cabin micro-superheated steam generator be started and stopped with one button?

Can.

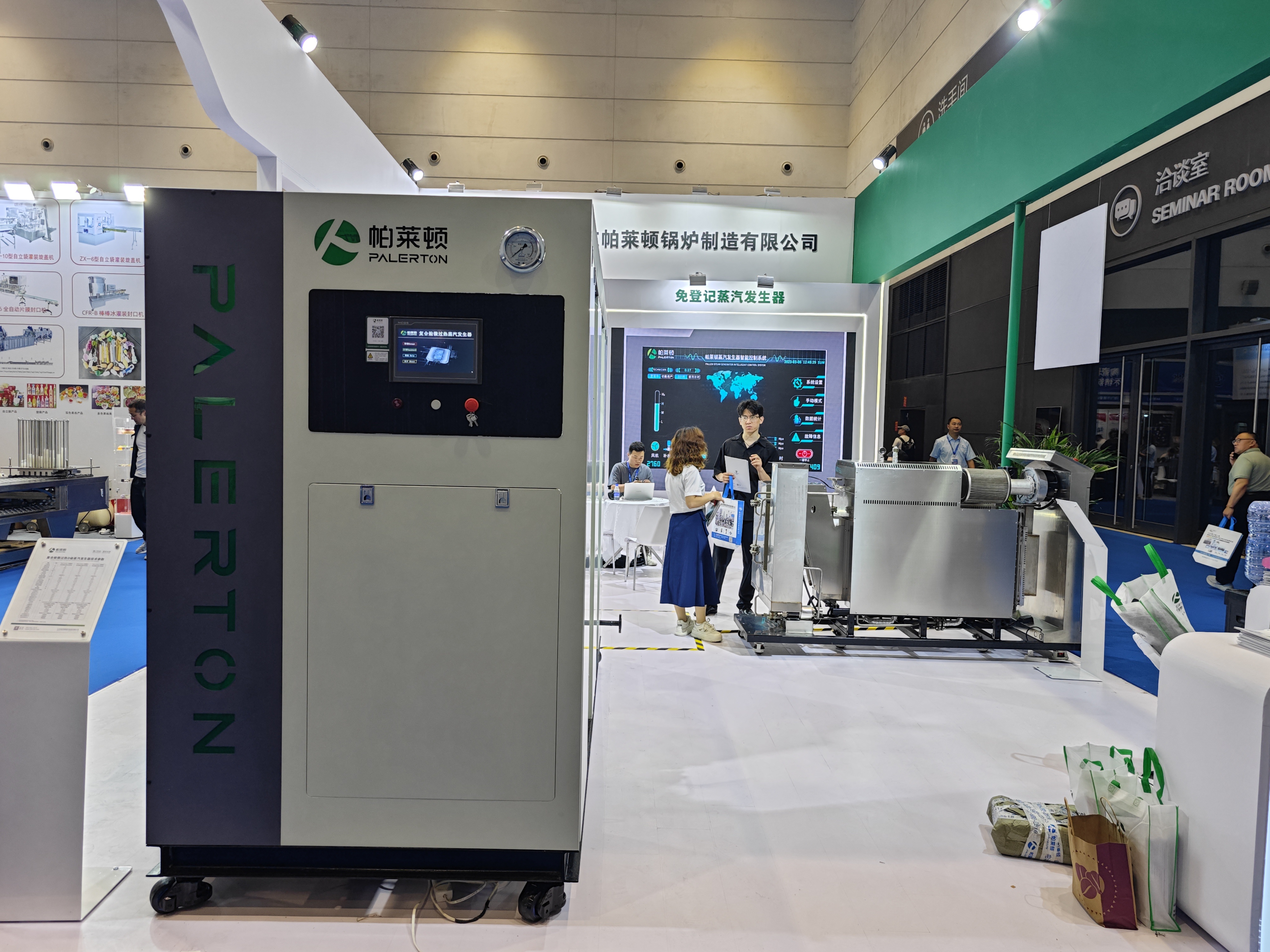

In modern industrial production, steam generators are key equipment, and their performance directly affects production efficiency and product quality. The composite chamber micro-superheated steam generator stands out among many steam generators due to its many excellent features, especially the one-button start and stop function .

The composite cabin micro-superheated steam generator is extremely easy to operate. You only need to press a button to start and stop the equipment, and you can become proficient in it after simple training. This convenient operation method greatly reduces the threshold for enterprises to employ people, making it easy to start and stop the production process without complicated operation procedures and professional control.

From the working principle, the composite cabin micro-superheated steam generator is based on advanced heat exchange technology, which converts water into micro-superheated steam through a series of precise steps. It is highly automated through the intelligent control system, laying a solid foundation for the one-button start and stop function. Compared with traditional steam generators, the composite chamber micro-superheated steam generator has significant advantages. It not only has a fast startup speed, it can achieve cold start steam production in just 28 seconds, which is much faster than the 2 minutes of traditional steam generators and 30 minutes of traditional boilers, but also has a thermal efficiency of up to 101.17%, which greatly reduces energy consumption. At the same time, it can also achieve steam dryness ≥ 99.01%, ensuring the purity and dryness of steam, meeting the strict requirements of industrial production on steam quality.

Compared with traditional steam generators, the composite chamber micro-superheated steam generator has significant advantages. It not only has a fast startup speed, it can achieve cold start steam production in just 28 seconds, which is much faster than the 2 minutes of traditional steam generators and 30 minutes of traditional boilers, but also has a thermal efficiency of up to 101.17%, which greatly reduces energy consumption. At the same time, it can also achieve steam dryness ≥ 99.01%, ensuring the purity and dryness of steam, meeting the strict requirements of industrial production on steam quality. In practical applications, the one-button start-stop function allows the composite chamber micro-superheated steam generator to be used in many industries. In the food processing industry, the steam supply needs to be frequently started and stopped during the production process. The equipment can respond quickly to ensure the continuity and quality stability of food processing. In the chemical industry, the complex production process has extremely high requirements for the timeliness and stability of steam supply. The one-button start-stop function combined with stable steam output effectively guarantees the smooth progress of chemical production.

In practical applications, the one-button start-stop function allows the composite chamber micro-superheated steam generator to be used in many industries. In the food processing industry, the steam supply needs to be frequently started and stopped during the production process. The equipment can respond quickly to ensure the continuity and quality stability of food processing. In the chemical industry, the complex production process has extremely high requirements for the timeliness and stability of steam supply. The one-button start-stop function combined with stable steam output effectively guarantees the smooth progress of chemical production.

Related News

From the stable heat output in the workshop, to the continuously reduced costs on the books, to the easily met environmental monitoring data, the composite cabin micro-superheated steam generator has not only brought about a leap in production efficiency, but also an upgrade in the company's development philosophy. Choosing it means choosing to go hand in hand with high efficiency and environmental protection, ensuring that every bit of heat energy is used effectively and that every investment is converted into tangible benefits.

The intelligent control system of the composite chamber micro-superheated steam generator enables integrated and precise control of water, air, and power supply. This eliminates the resource waste associated with manual operation of traditional equipment, reducing steam consumption to as low as 75 Nm³/h per ton. This significantly reduces costs and makes the composite chamber micro-superheated steam generator a key driver for cost reduction and efficiency improvement in the oil extraction industry. Furthermore, the composite chamber micro-superheated steam generator can also be used in the degumming and bleaching processes of oil extraction plants, accelerating the separation of phospholipids from oil, reducing the use of chemical reagents, reducing residual impurities, and improving the light transmittance of the finished oil.

The composite cabin micro-superheated steam generator ensures a stable supply of paper in a more environmentally friendly and efficient way. It also allows us to enjoy the convenience of school supplies while contributing invisible strength to protecting the green environment and promoting sustainable industrial development.

The Role of a Composite Chamber Micro-Superheated Steam Generator in the Ironing Process

In general, the composite cabin micro-superheated steam generator, with its high steam dryness, high thermal efficiency, and rapid steam output, significantly improves ironing quality, reduces energy consumption, and improves work efficiency during the ironing process, bringing efficient and high-quality solutions to the ironing field.

What are the advantages of steam generators when cleaning medical textiles?

Furthermore, the generator is easy to operate and safe and reliable. It features an intelligent control system that adjusts steam temperature, pressure, and flow rate via the Internet of Things. Multiple safety protection devices ensure stable operation, reducing maintenance costs and potential safety hazards. Regarding environmental performance, its nitrogen oxide emissions are ≤20mg/m³, far exceeding national environmental standards and contributing to a green medical environment.

The Role of the Steam Generator in the Washing Process

The composite chamber slightly superheated steam generator, with its 230°C high temperature and 100% dryness, delivers deep cleansing and highly effective sterilization. Whether for daily household laundry or commercial batch washing, it balances fabric protection with ecological responsibility while ensuring effective cleaning. It has become an irreplaceable core device in modern laundry scenarios, providing a dual impetus for clean living and green development.