What are the advantages of steam generators in steam sterilization?

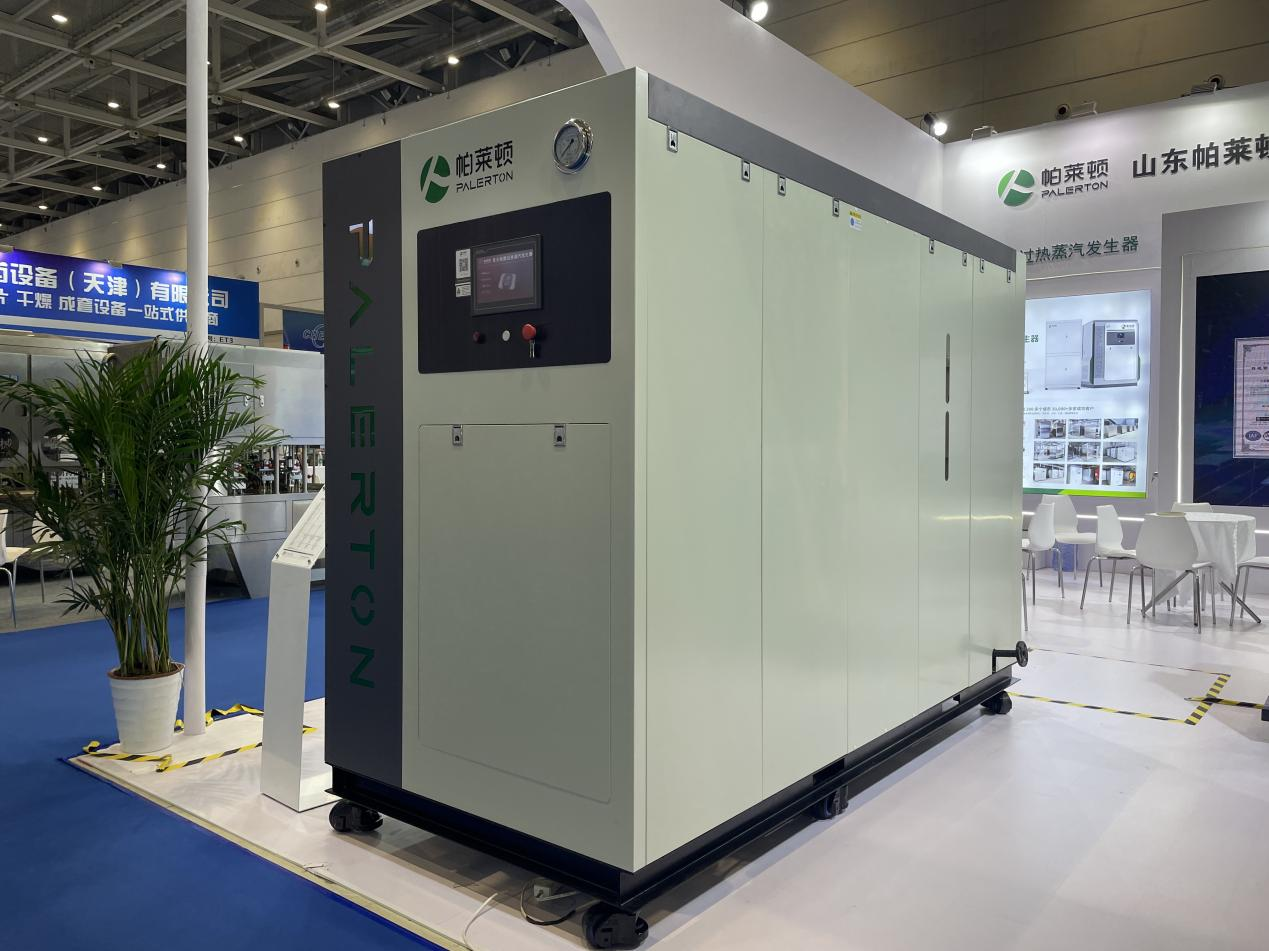

Steam sterilization is a key technology for ensuring safety in the medical, food, and pharmaceutical industries. From preserving canned food to sterilizing laboratory instruments, steam sterilization is essential. As the core equipment in this process, the composite chamber micro-superheated steam generator has become the industry's preferred choice due to its multiple advantages. The composite cabin micro-superheated steam generator adopts a direct-flow heat exchange structure design, which can produce micro-superheated steam with low pressure and high temperature. The maximum temperature of superheated steam can reach 230°C. The humidity of saturated steam can be adjusted, and the dryness can reach 100%. It has extremely low water content and strong penetrating power, and can penetrate into every gap of sterilized items. It can completely kill all kinds of microorganisms including spores at high temperatures of 121°C~134°C, ensuring stable and reliable sterilization effect.

The composite cabin micro-superheated steam generator adopts a direct-flow heat exchange structure design, which can produce micro-superheated steam with low pressure and high temperature. The maximum temperature of superheated steam can reach 230°C. The humidity of saturated steam can be adjusted, and the dryness can reach 100%. It has extremely low water content and strong penetrating power, and can penetrate into every gap of sterilized items. It can completely kill all kinds of microorganisms including spores at high temperatures of 121°C~134°C, ensuring stable and reliable sterilization effect. The composite chamber micro-superheated steam generator offers highly controllable temperature and pressure, allowing flexible adjustment of parameters based on the characteristics of individual items, eliminating sterilization "blind spots." Equipped with a proprietary energy-saving control system, the composite chamber micro-superheated steam generator maintains pressure fluctuations within ±0.01 MPa. Furthermore, it boasts rapid startup, generating steam in just 28 seconds, significantly reducing setup time and improving efficiency in batch sterilization scenarios.

The composite chamber micro-superheated steam generator offers highly controllable temperature and pressure, allowing flexible adjustment of parameters based on the characteristics of individual items, eliminating sterilization "blind spots." Equipped with a proprietary energy-saving control system, the composite chamber micro-superheated steam generator maintains pressure fluctuations within ±0.01 MPa. Furthermore, it boasts rapid startup, generating steam in just 28 seconds, significantly reducing setup time and improving efficiency in batch sterilization scenarios. Furthermore, modern steam generators combine energy conservation and environmental protection with safety and convenience. High-efficiency heat exchange technology reduces energy waste, while intelligent systems enable precise temperature control. The composite chamber slightly superheated steam generator utilizes a water-cooled, fully premixed burner, achieving a 100% burnout rate and a total thermal efficiency of 101.21%. Emissions of nitrogen oxides and other substances are ≤20mg/m³, demonstrating excellent environmental performance. The combination of a water-cooled, fully premixed structure and an intelligent control system provides multiple protections to prevent accidents. The compact design adapts to a variety of locations and simplifies installation and maintenance.

Furthermore, modern steam generators combine energy conservation and environmental protection with safety and convenience. High-efficiency heat exchange technology reduces energy waste, while intelligent systems enable precise temperature control. The composite chamber slightly superheated steam generator utilizes a water-cooled, fully premixed burner, achieving a 100% burnout rate and a total thermal efficiency of 101.21%. Emissions of nitrogen oxides and other substances are ≤20mg/m³, demonstrating excellent environmental performance. The combination of a water-cooled, fully premixed structure and an intelligent control system provides multiple protections to prevent accidents. The compact design adapts to a variety of locations and simplifies installation and maintenance. The composite chamber micro-superheated steam generator plays an irreplaceable role in the steam sterilization process with its multiple advantages such as excellent steam quality, precise control capabilities, efficient startup speed, energy saving and environmental protection, safety and convenience, etc., providing solid and reliable guarantees for sterile production in the fields of medical, food, pharmaceuticals, etc., and becoming an important force in promoting the safe development of various industries.

The composite chamber micro-superheated steam generator plays an irreplaceable role in the steam sterilization process with its multiple advantages such as excellent steam quality, precise control capabilities, efficient startup speed, energy saving and environmental protection, safety and convenience, etc., providing solid and reliable guarantees for sterile production in the fields of medical, food, pharmaceuticals, etc., and becoming an important force in promoting the safe development of various industries.

Related News

What are the advantages of steam generators in steam sterilization?

The composite chamber micro-superheated steam generator plays an irreplaceable role in the steam sterilization process with its multiple advantages such as excellent steam quality, precise control capabilities, efficient startup speed, energy saving and environmental protection, safety and convenience, etc., providing solid and reliable guarantees for sterile production in the fields of medical, food, pharmaceuticals, etc., and becoming an important force in promoting the safe development of various industries.

Why Steam Generators Are Energy-Efficient

In short, the steam generator improves efficiency throughout the entire process from energy generation to heat utilization by strictly controlling steam saturation and effectively controlling exhaust gas temperature, demonstrating its energy-saving advantages and injecting momentum into industrial cost reduction and green production.

What steam generator capacity should I buy?

In addition, factors such as equipment performance, installation space, budget, and after-sales service also need to be comprehensively considered when selecting a steam generator. Only by comprehensively and scientifically analyzing these factors can you select the steam generator that best suits your needs, ensuring efficient and stable production and improving economic benefits.

Steam Generator Working Principle

The steam generator is also equipped with multiple safety protection devices, such as a pressure safety valve, a water level controller, and over-temperature protection, to ensure timely shutdown in abnormal situations and avoid accidents. Through this cyclic process, the steam generator can continuously and stably produce steam at a certain pressure and temperature to meet the energy needs of different scenarios.

What impact do steam generators have on the environment?

With their advanced technology, exceptional environmental performance, and remarkable achievements in practical applications, steam generators provide a practical solution for balancing industrial production and ecological protection. They are not only a powerful aid for industrial enterprises to achieve green production, but also a key engine driving the entire industrial sector's transition toward sustainable development.

From efficient industrial production to safety assurance in the medical field, from improving feed processing quality to precisely supporting scientific research experiments, steam generators, with their diverse functions, are deeply integrated into the core links of various industries. They are not only a vital carrier of energy conversion, but also a solid backing for promoting production progress and scientific research innovation, continuously injecting indispensable power into social development.