What are the features of a Palerton steam generator

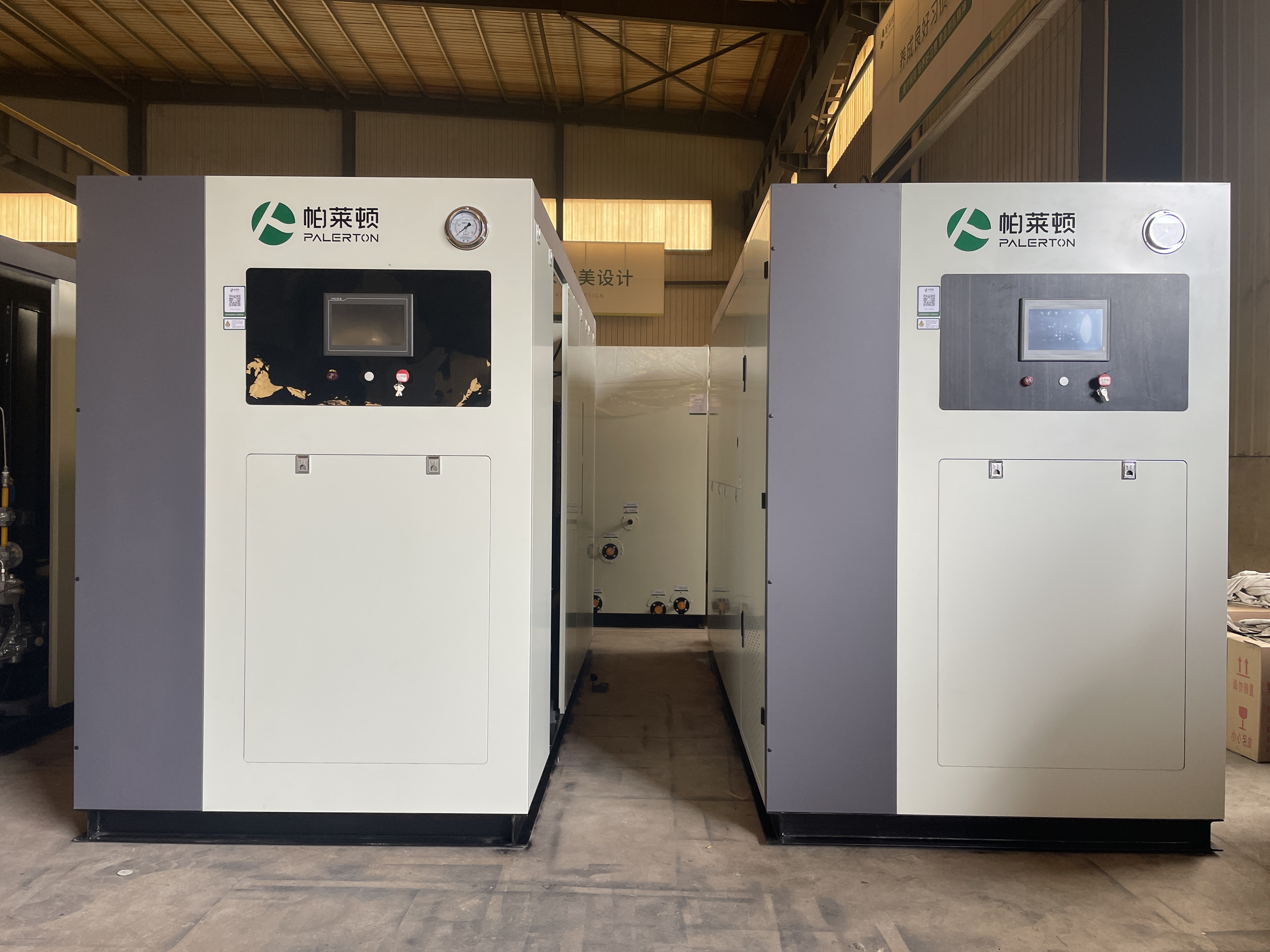

In the field of industrial steam equipment, Palerton steam generators have become the trusted choice of many companies for their unique and outstanding performance, providing efficient, stable and environmentally friendly steam solutions for production processes.

The equipment has been upgraded with “PLD - iPower2.0” energy-saving control system, which utilizes full frequency conversion PID intelligent operation technology to adjust the equipment operation parameters in real time and accurately according to the actual steam demand. It not only ensures the stable supply of steam, but also effectively avoids energy waste, controlling the gas consumption of tons of steam at 75m³/h, further enhancing the energy-saving effect and operational stability of the equipment, and providing solid support for the sustainable development of the enterprise.

In terms of thermal efficiency, the performance of Palerton steam generator is amazing, up to 101.21%. It adopts advanced heat exchange technology and high-efficiency combustion system, through optimizing the combustion process and strengthening heat recovery, it realizes the maximum utilization of energy and significantly reduces the enterprise's energy consumption and operating costs.

In terms of environmental performance, after upgrading to a water-cooled full pre-mixed burner, the steam generator's NOx emissions are less than 21mg/m³, and CO emissions tend to be close to 0, which is far better than many similar products and stringent environmental standards. This is due to its innovative low-NOx combustion technology, which effectively controls the generation of NOx in the combustion process while reducing pollution to the environment, helping companies easily reach their environmental goals.

It is worth mentioning that the steam humidity of Palerton steam generator “adjustable” “micro-superheating” Continuous and stable output, can achieve superheated steam dryness of up to 100%, to achieve the degree of superheat 20 ℃ -30 ℃, the highest temperature up to 230 ℃. Whether the steam dryness requirements of the special process, or the need to accurately regulate the steam humidity to meet the needs of different production processes, it is perfectly capable of providing stable and reliable steam conditions for the production process, a strong guarantee of the consistency and stability of product quality. In addition, one of the outstanding features of Palerton's steam generators is the exemption from inspection, which greatly simplifies the preliminary procedures for the use of the equipment and the subsequent regulatory process, saving a great deal of time and effort for the enterprise, so that it can focus more on the core production business.

In addition, one of the outstanding features of Palerton's steam generators is the exemption from inspection, which greatly simplifies the preliminary procedures for the use of the equipment and the subsequent regulatory process, saving a great deal of time and effort for the enterprise, so that it can focus more on the core production business.

Related News

What can a gas steam generator do during the production of chili sticks?

It can be said that the gas steam generator by virtue of its own advantages throughout the production of chili, each step is inseparable from its help, a strong guarantee of chili's deliciousness and quality, and promote the chili industry continues to grow and develop.

What can steam generators be used for?

As industrial technology continues to advance, steam generators are also developing in the direction of greater energy efficiency and intelligence. In the future, steam generators will continue to empower industries to promote a green and sustainable industrial development model while improving production efficiency and ensuring product quality.

The role of steam generators in the production of nutrient soils

These properties allow steam generators to play a key role in soil sterilization. High-temperature steam can quickly penetrate the soil layer and efficiently kill soil pathogenic bacteria, such as Fusarium and Fusarium oxysporum, as well as insect eggs and weed seeds. Steam penetrates up to 30 - 50 centimeters into the soil, which is effective in deep sterilization and helps to solve the problem of continuous crop failure.

What are the features of a Palerton steam generator

In addition, one of the outstanding features of Palerton's steam generators is the exemption from inspection, which greatly simplifies the preliminary procedures for the use of the equipment and the subsequent regulatory process, saving a great deal of time and effort for the enterprise, so that it can focus more on the core production business.

What are the advantages of a steam generator over a boiler?

Whether it is the subversion of the traditional speed of response, or nearly extreme energy conversion efficiency, or watertight intelligent safety protection, have made it become the enterprise cost reduction and efficiency, breakthroughs in production capacity bottlenecks of the core weapon. When the limitations of the traditional boiler has gradually become a shackle on the development of enterprises, gas steam generator is more agile adaptability, more powerful productivity and more reliable safety, drive industrial production to a higher form of evolution, for the modern industry to inject a steady stream of surging kinetic energy.

The role of steam generator in the production process of rubber gloves

Therefore, the steam generator throughout the production of rubber gloves, from raw material processing to the final vulcanization, to enhance production efficiency, product quality and so on play an irreplaceable role in guaranteeing the quality of products, rubber gloves is an indispensable and important equipment for the production of enterprises.