What can steam generators be used for?

In modern industrial production, steam generators have become an indispensable core piece of equipment for a wide range of industries, thanks to their efficient and flexible heating characteristics. From demanding biopharmaceuticals to traditional textile printing and dyeing, steam generators have been injecting critical kinetic energy into production, driving industries to achieve efficient and stable process goals.

In the biopharmaceutical industry, asepsis and precise temperature control is the lifeline of production, steam generator plays an irreplaceable role here. In the sterilization of equipment and appliances, 121 ℃ saturated steam can be on the reactor, piping and other in-depth sterilization, to ensure that the production environment in line with GMP standards (to ensure the quality, safety, and effectiveness of drugs); in the preparation of culture medium, steam heating can effectively kill stray bacteria, to ensure the purity of the culture of strains; concentration and drying of drugs in the process of steam to help evaporation of the liquid, drying of the powder to ensure that the quality and safety of medicines, and to ensure that the moisture content of strict control. In the process of drug concentration and drying, steam helps the evaporation of liquid medicine and drying of powder, strictly control the moisture content and ensure the quality and safety of medicine.

In the feed processing industry, steam generators are applied around the improvement of feed quality and safety. Before granulation, steam tempering softens raw materials and improves the molding rate and digestibility; high-temperature steam kills harmful microorganisms during maturation and reduces the risk of feed mold; in the production of puffed feed, the instantaneous expansion of steam gives the feed an easy-to-digest performance; and in the drying process of the feed, steam accurately controls the moisture and prolongs the storage period.

The washing industry has realized the double enhancement of washing effect and efficiency with the help of steam generator. In the clothing and fabric washing, steam heating washing water to enhance the ability to remove dirt, high temperature can also kill bacteria mites, to meet the hospitals, hotels and other knitted items to meet the strict needs of the elimination of ironing; ironing the ironing process, the steam makes the fiber soften, so that the clothing is as flat as new, coupled with superheated steam dryness of up to 100%, ironing after the clothing is also no water stains remain, which can be finished products to maintain the beauty of the.

The whole process of pre-treatment, dyeing and finishing in the printing and dyeing industry is inseparable from the steam generator. From desizing and boiling to dyeing and color fixing, steam precisely regulates the temperature and humidity in each step to ensure bright colors and excellent performance of fabrics.

As industrial technology continues to advance, steam generators are also developing in the direction of greater energy efficiency and intelligence. In the future, steam generators will continue to empower industries to promote a green and sustainable industrial development model while improving production efficiency and ensuring product quality.

Related News

What can a gas steam generator do during the production of chili sticks?

It can be said that the gas steam generator by virtue of its own advantages throughout the production of chili, each step is inseparable from its help, a strong guarantee of chili's deliciousness and quality, and promote the chili industry continues to grow and develop.

What can steam generators be used for?

As industrial technology continues to advance, steam generators are also developing in the direction of greater energy efficiency and intelligence. In the future, steam generators will continue to empower industries to promote a green and sustainable industrial development model while improving production efficiency and ensuring product quality.

The role of steam generators in the production of nutrient soils

These properties allow steam generators to play a key role in soil sterilization. High-temperature steam can quickly penetrate the soil layer and efficiently kill soil pathogenic bacteria, such as Fusarium and Fusarium oxysporum, as well as insect eggs and weed seeds. Steam penetrates up to 30 - 50 centimeters into the soil, which is effective in deep sterilization and helps to solve the problem of continuous crop failure.

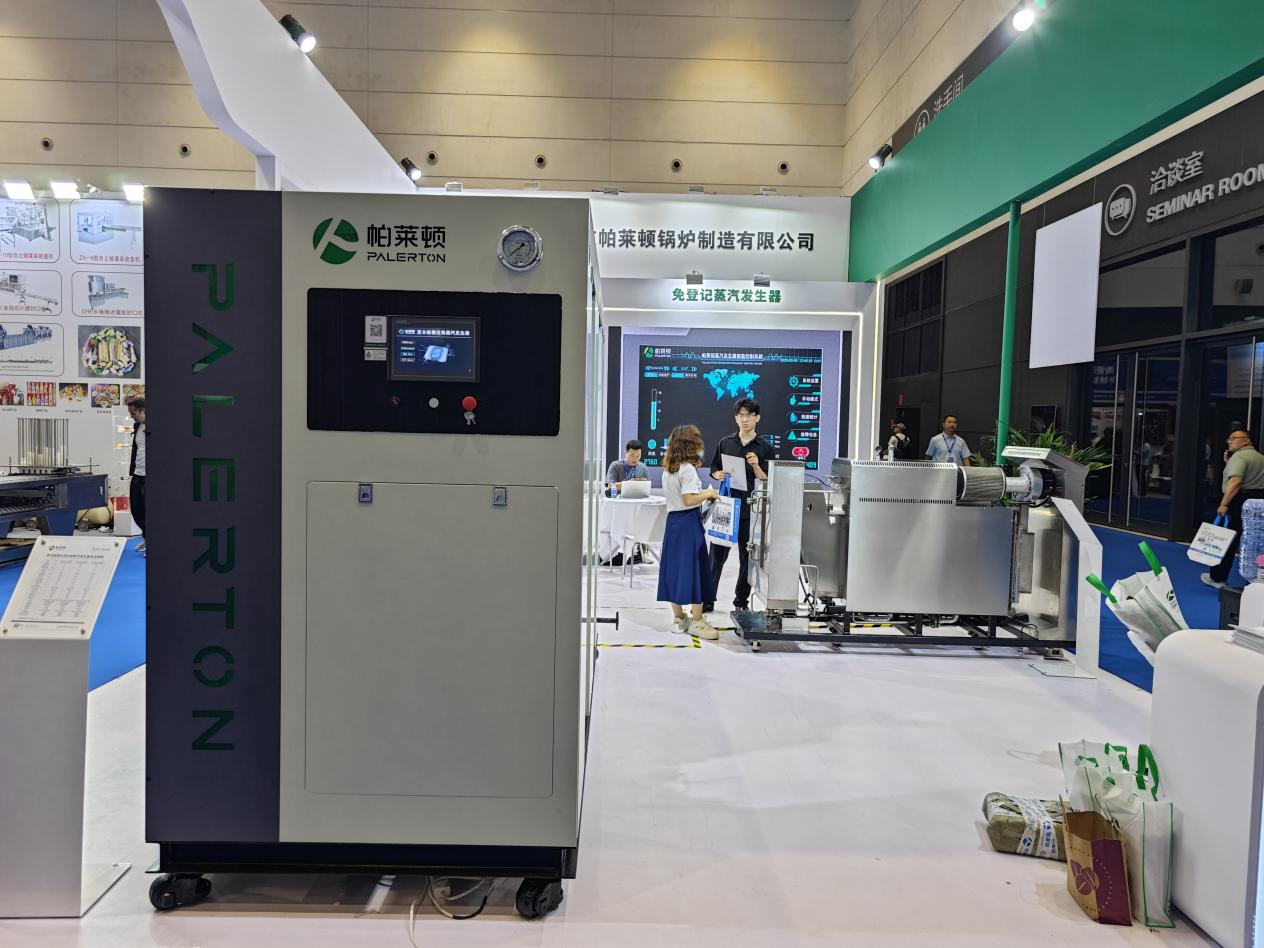

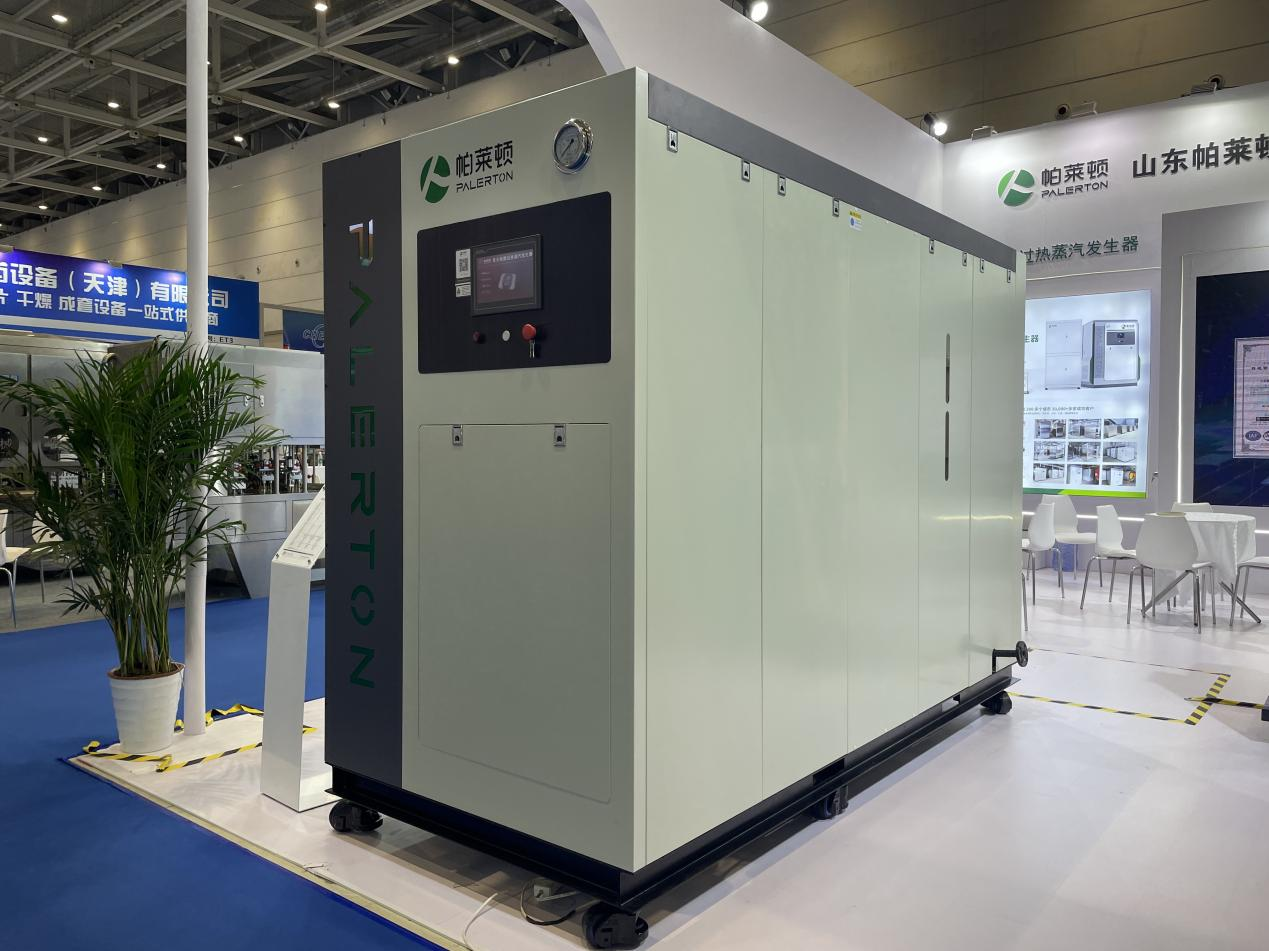

What are the features of a Palerton steam generator

In addition, one of the outstanding features of Palerton's steam generators is the exemption from inspection, which greatly simplifies the preliminary procedures for the use of the equipment and the subsequent regulatory process, saving a great deal of time and effort for the enterprise, so that it can focus more on the core production business.

What are the advantages of a steam generator over a boiler?

Whether it is the subversion of the traditional speed of response, or nearly extreme energy conversion efficiency, or watertight intelligent safety protection, have made it become the enterprise cost reduction and efficiency, breakthroughs in production capacity bottlenecks of the core weapon. When the limitations of the traditional boiler has gradually become a shackle on the development of enterprises, gas steam generator is more agile adaptability, more powerful productivity and more reliable safety, drive industrial production to a higher form of evolution, for the modern industry to inject a steady stream of surging kinetic energy.

The role of steam generator in the production process of rubber gloves

Therefore, the steam generator throughout the production of rubber gloves, from raw material processing to the final vulcanization, to enhance production efficiency, product quality and so on play an irreplaceable role in guaranteeing the quality of products, rubber gloves is an indispensable and important equipment for the production of enterprises.