What are the advantages of a water-cooled combustion plate?

In the field of industrial production and energy utilization, the post-premixing mode of the composite cabin micro-superheated steam generator has demonstrated many significant advantages, providing strong support for the efficient, environmentally friendly and stable operation of the equipment.

In terms of service life, its water-cooled post-premix combustion disk uses water cooling to avoid high-temperature damage, reduce maintenance frequency, save maintenance costs, greatly improve the cost performance of the equipment, and make the equipment more durable in long-term operation.

In terms of energy saving, the post-premix mode adds a mother fire mode. When the steam pressure is higher than the set value, the load is reduced and the machine does not stop, avoiding the waste of start and stop, effectively saving energy, helping enterprises reduce energy consumption costs, and meeting the current energy-saving production needs.

The environmental performance is particularly outstanding, with NOx≤21mg/m³ and CO emissions close to 0, far exceeding industry standards. In today's increasingly stringent environmental protection requirements, it can help companies reduce pollutant emissions and practice green production concepts.

In terms of safety, the post-premix patented air mixer plays a key role, effectively suppressing flameout and flashback, avoiding accidents caused by explosions, and building a solid safety line for equipment operation and production environment.

In terms of combustion efficiency, the pressure in the wind chamber is evenly distributed, the flame on the combustion surface is flat, and the fuel burnout rate reaches 100%, which reduces the company's fuel waste costs, improves energy utilization efficiency, and allows every fuel to be fully converted into productivity.

Operation stability is guaranteed, there are no wearing parts, upgraded ultraviolet flame detectors, no air filters are required, maintenance costs are reduced, and equipment is ensured to operate continuously and stably, reducing the interference of shutdown maintenance on production.

In terms of noise, the fan has a low speed, high wind pressure, and low noise, creating a quieter production environment and improving working conditions.

Related News

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.

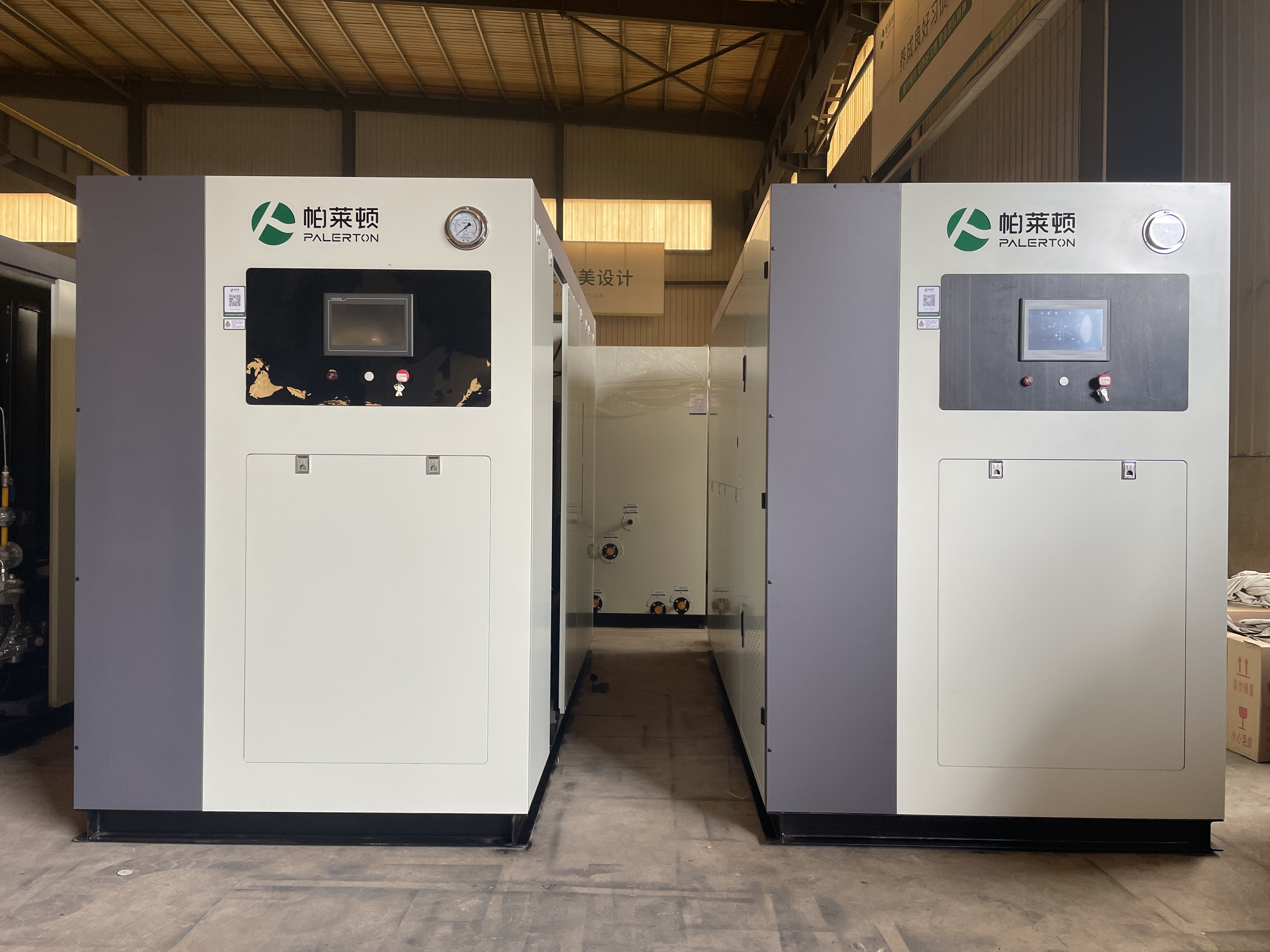

Principle of Composite Chamber Slightly Superheated Steam Generator

This equipment offers significant advantages: no inspection required, no permits needed, and no manual operation. It consumes ≤75m³ of gas per ton of steam produced per hour, with 100% steam dryness, a boiler thermal efficiency of up to 101.21%, and a maximum superheated steam temperature of 230°C. Nitrogen oxide emissions are ≤20mg/m³, while carbon monoxide emissions approach zero. It excels in energy efficiency, environmental protection, safety, and convenience, making it suitable for diverse industrial applications.