What food industries can steam generators be used in?

In the food industry, steam generators play a critical role, and composite chamber slightly superheated steam generators, with their unique advantages, are widely used across multiple specialized sectors. In the food steaming process, it delivers outstanding performance. Take dough proofing in bread making as an example: the composite chamber superheated steam generator produces steam in just 28 seconds, rapidly creating a high-temperature, high-humidity environment that facilitates quick and uniform fermentation. This results in finished bread with excellent fluffiness and consistent texture. When steaming staples like rice and buns, it precisely controls temperature to ensure thorough cooking while maximizing the retention of nutrients.

In the food steaming process, it delivers outstanding performance. Take dough proofing in bread making as an example: the composite chamber superheated steam generator produces steam in just 28 seconds, rapidly creating a high-temperature, high-humidity environment that facilitates quick and uniform fermentation. This results in finished bread with excellent fluffiness and consistent texture. When steaming staples like rice and buns, it precisely controls temperature to ensure thorough cooking while maximizing the retention of nutrients.

In food sterilization, it also excels. For canned goods, beverages, and other foods, the high-temperature steam generated by the composite chamber subcritical steam generator—reaching up to 230°C—effectively eliminates bacteria, viruses, and other microorganisms. In canned food production, the steam's high temperature and pressure penetrate deep into the food, achieving thorough sterilization. This ensures food safety, extends shelf life, and avoids residue issues associated with chemical sterilization. In the realm of food drying and baking, it is equally indispensable. When producing dried fruits and vegetables, the composite chamber superheated steam generator produces steam with 100% dryness, rapidly removing moisture while preserving the original color and flavor of the produce. For baking bread and pastries, the generator delivers stable steam, resulting in a crispy crust and a soft interior, thereby enhancing product quality.

In the realm of food drying and baking, it is equally indispensable. When producing dried fruits and vegetables, the composite chamber superheated steam generator produces steam with 100% dryness, rapidly removing moisture while preserving the original color and flavor of the produce. For baking bread and pastries, the generator delivers stable steam, resulting in a crispy crust and a soft interior, thereby enhancing product quality. In puffed food production, the steam rapidly generated by the generator enables raw materials to reach optimal temperature and humidity within a short timeframe, promoting starch gelatinization and enhancing the product's crispy texture. Furthermore, its intelligent control system precisely regulates temperature and humidity, allowing flexible adjustment between saturated steam and slightly superheated steam. This reduces defect rates and boosts production efficiency.

In puffed food production, the steam rapidly generated by the generator enables raw materials to reach optimal temperature and humidity within a short timeframe, promoting starch gelatinization and enhancing the product's crispy texture. Furthermore, its intelligent control system precisely regulates temperature and humidity, allowing flexible adjustment between saturated steam and slightly superheated steam. This reduces defect rates and boosts production efficiency. The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

Related News

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.

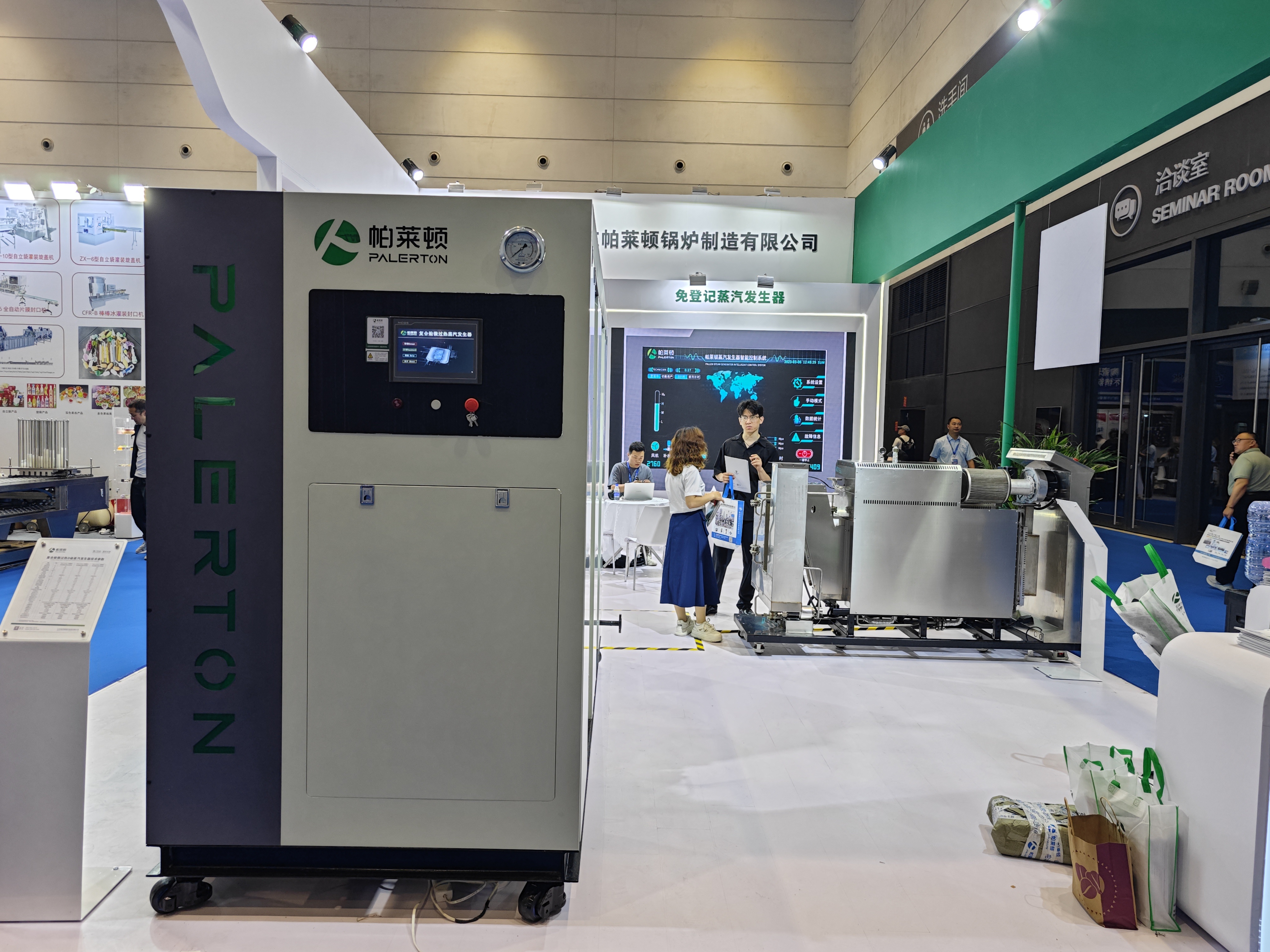

Principle of Composite Chamber Slightly Superheated Steam Generator

This equipment offers significant advantages: no inspection required, no permits needed, and no manual operation. It consumes ≤75m³ of gas per ton of steam produced per hour, with 100% steam dryness, a boiler thermal efficiency of up to 101.21%, and a maximum superheated steam temperature of 230°C. Nitrogen oxide emissions are ≤20mg/m³, while carbon monoxide emissions approach zero. It excels in energy efficiency, environmental protection, safety, and convenience, making it suitable for diverse industrial applications.