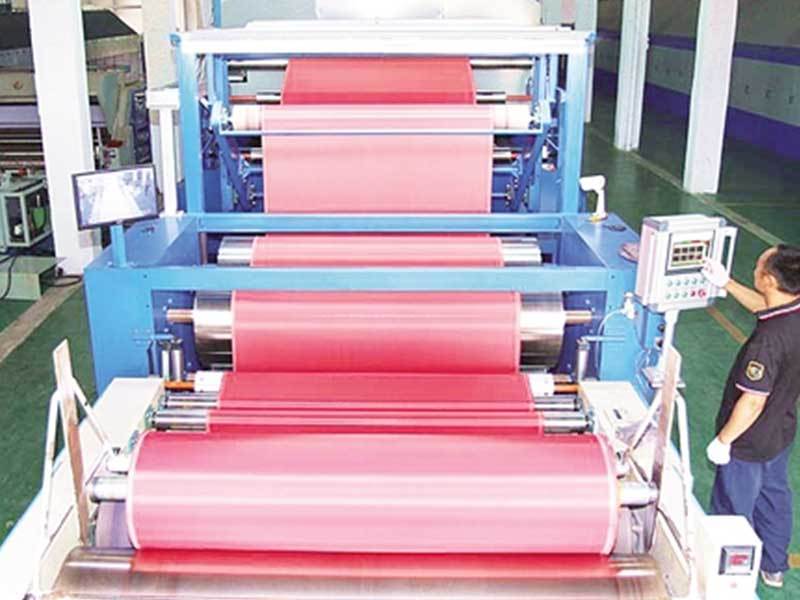

The role of steam generator in printing and dyeing process

Printing and dyeing is a process that dyes, prints, and finishes grey fabrics to give them rich colors and specific functions. In this complex process, the steam generator is the core "power source". Its efficient and stable steam supply greatly improves the quality of printing and dyeing and production efficiency.

Steam generators have significant characteristics.

The first is high efficiency. It can quickly convert water into steam and reach the required temperature and pressure in a short time, providing a continuous and stable heat source for high-temperature dyeing, steaming and fixing in printing and dyeing, and reducing production waiting time.

The second is precise temperature control. According to the requirements of different printing and dyeing processes, the steam temperature can be accurately controlled within a specific range to ensure uniform adhesion of dyes and avoid color differences. The third is energy conservation and environmental protection, using advanced combustion technology and efficient heat exchange system to improve energy utilization and reduce pollutant emissions, which is in line with the current green production concept. The fourth is safety and reliability, equipped with multiple safety protection devices, such as pressure protection and water level protection, to prevent dangerous situations such as overpressure and dry burning.

The third is energy conservation and environmental protection, using advanced combustion technology and efficient heat exchange system to improve energy utilization and reduce pollutant emissions, which is in line with the current green production concept. The fourth is safety and reliability, equipped with multiple safety protection devices, such as pressure protection and water level protection, to prevent dangerous situations such as overpressure and dry burning. Steam generators are widely used in the printing and dyeing process. During dyeing, high-temperature steam can accelerate the movement of dye molecules, allowing the dye to better penetrate into the fiber; after printing, steam can allow the dye to fully react with the fiber to improve color fastness; during fabric washing and drying, steam can improve the cleaning effect and speed up the drying process. With these characteristics and functions, steam generators occupy an indispensable position in the printing and dyeing industry, driving the industry to develop in the direction of high efficiency, high quality and green.

Steam generators are widely used in the printing and dyeing process. During dyeing, high-temperature steam can accelerate the movement of dye molecules, allowing the dye to better penetrate into the fiber; after printing, steam can allow the dye to fully react with the fiber to improve color fastness; during fabric washing and drying, steam can improve the cleaning effect and speed up the drying process. With these characteristics and functions, steam generators occupy an indispensable position in the printing and dyeing industry, driving the industry to develop in the direction of high efficiency, high quality and green.

Related News

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.

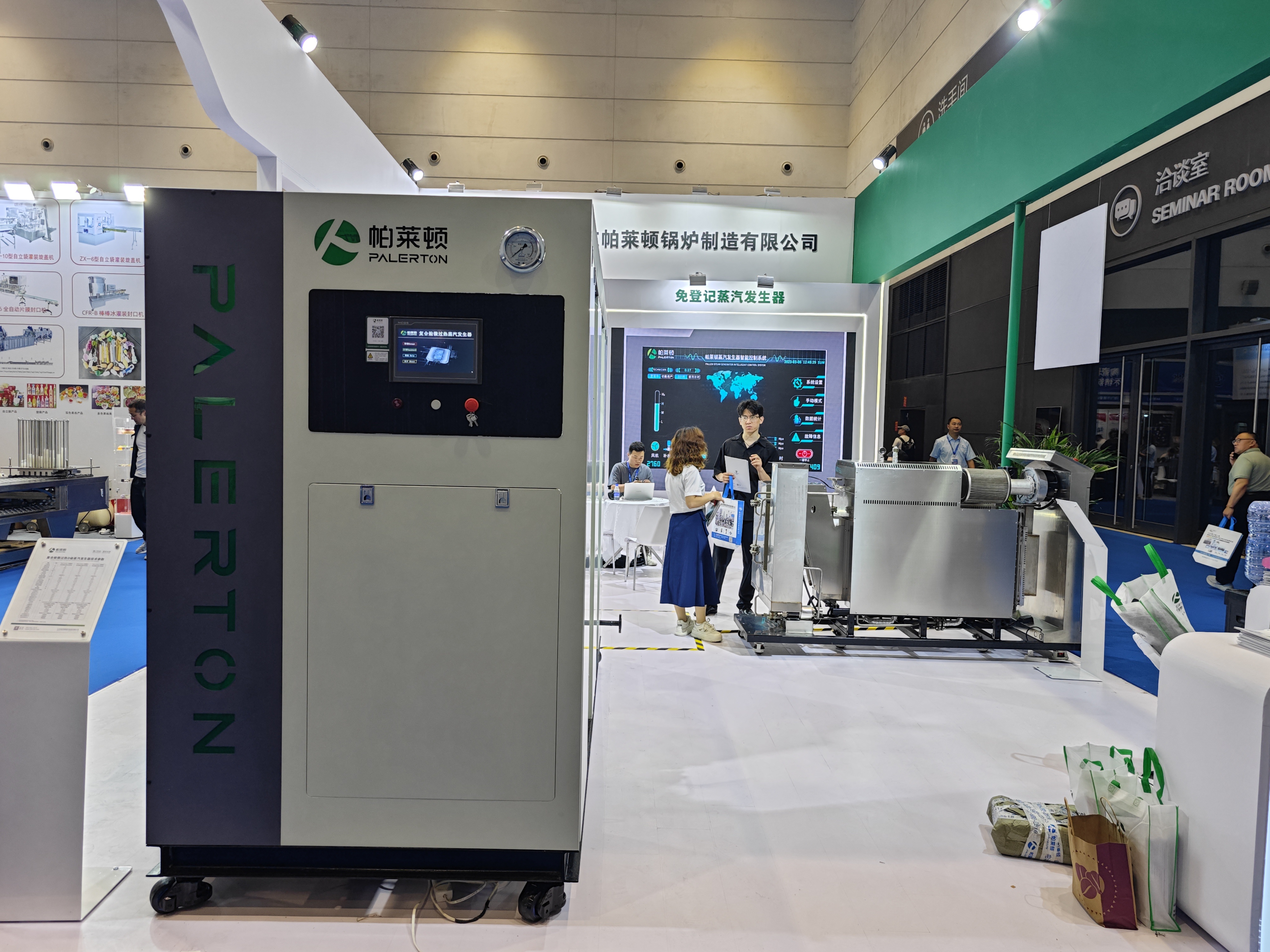

Principle of Composite Chamber Slightly Superheated Steam Generator

This equipment offers significant advantages: no inspection required, no permits needed, and no manual operation. It consumes ≤75m³ of gas per ton of steam produced per hour, with 100% steam dryness, a boiler thermal efficiency of up to 101.21%, and a maximum superheated steam temperature of 230°C. Nitrogen oxide emissions are ≤20mg/m³, while carbon monoxide emissions approach zero. It excels in energy efficiency, environmental protection, safety, and convenience, making it suitable for diverse industrial applications.