Characteristics of Micro-superheated Steam Generator in Composite Cabin

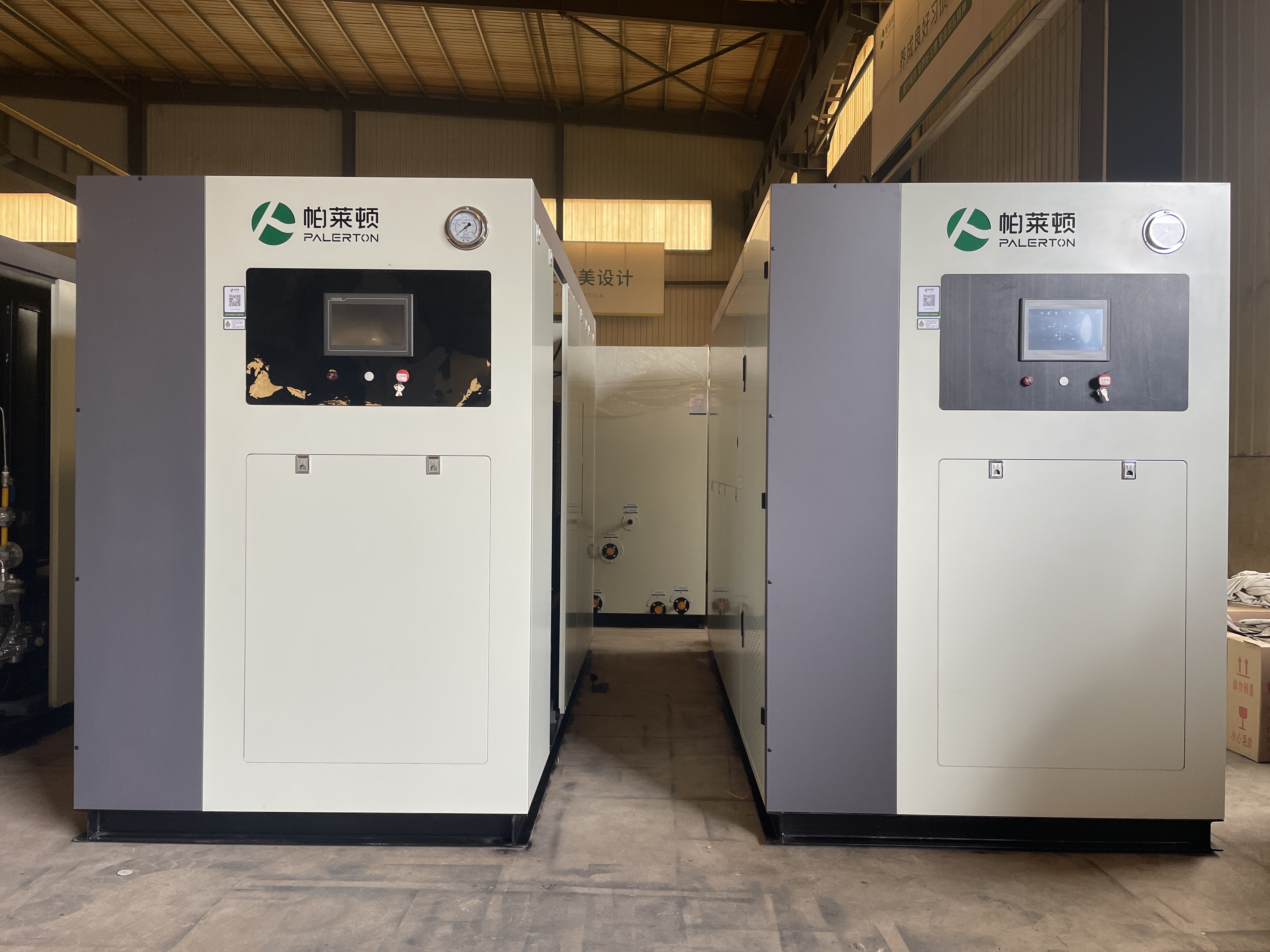

The composite cabin micro-superheated steam generator has become an innovative work in the field of industrial steam thanks to its innovative thermodynamic design and breakthroughs in material science.

The composite cabin micro-superheated steam generator adopts a water-cooled fully premixed burner, achieving a thermal efficiency of up to 101.21%. This value is achieved thanks to the 100% burnout rate of the composite cabin micro-superheated steam generator, while CO emissions are close to 0 and the surface temperature of the furnace is below 45°C.

In terms of energy consumption control, the composite cabin micro-superheated steam generator shows significant advantages. Under normal conditions, the gas consumption per ton of steam is only 75m³/h. When connected to 100°C high-temperature return water, this value can be further reduced to 70m³/h. Through the coordinated operation of the intelligent heat circulation system and the high-efficiency heat exchanger, the composite cabin micro-superheated steam generator reduces energy consumption and significantly reduces operating costs for enterprises.

The composite cabin micro-superheated steam generator can achieve precise temperature and pressure control, ensuring that the steam dryness is stable at 100%, while also achieving "adjustable" steam humidity. It is truly low-pressure and high-temperature, with a maximum temperature of 230°C, meeting the needs of industries such as feed, ironing and dyeing that have high requirements for steam quality.

In terms of environmental performance, the composite cabin micro-superheated steam generator has nitrogen oxide emissions of ≤21mg/m³ and CO emissions of almost zero, far exceeding the national environmental protection standards (the standard for first-tier cities is 30mg/m³), providing a practical solution for the balance between industrial production and ecological protection.

Related News

The Role of the Steam Generator in the Washing Process

The composite chamber slightly superheated steam generator, with its 230°C high temperature and 100% dryness, delivers deep cleansing and highly effective sterilization. Whether for daily household laundry or commercial batch washing, it balances fabric protection with ecological responsibility while ensuring effective cleaning. It has become an irreplaceable core device in modern laundry scenarios, providing a dual impetus for clean living and green development.

What is the role of the steam generator in the harmless treatment process?

The composite chamber micro-superheated steam generator not only relies on high-temperature and high-pressure micro-superheated steam to efficiently complete key links such as sterilization and degradation, building a solid line of defense for the harmlessness of pollutants, but also with its compact size, excellent thermal efficiency and ultra-low pollutant emissions, it balances the treatment effect with multiple needs of environmental protection and economy, helping harmless treatment to truly achieve an efficient, green and sustainable virtuous cycle.

What is the purpose of steam generators in the pharmaceutical manufacturing process?

From precise temperature and pressure control to outstanding energy efficiency, the composite chamber micro-superheated steam generator comprehensively meets the pharmaceutical industry's multifaceted demands for process stability, safety, and cost-effectiveness. It not only provides reliable steam supply for drug production but also drives the optimization and upgrading of pharmaceutical processes through technological innovation. This makes it a vital enabler for modern pharmaceutical enterprises to enhance their core competitiveness, injecting sustained momentum into the high-quality development of the pharmaceutical sector.

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.