What is the purpose of steam generators in the pharmaceutical manufacturing process?

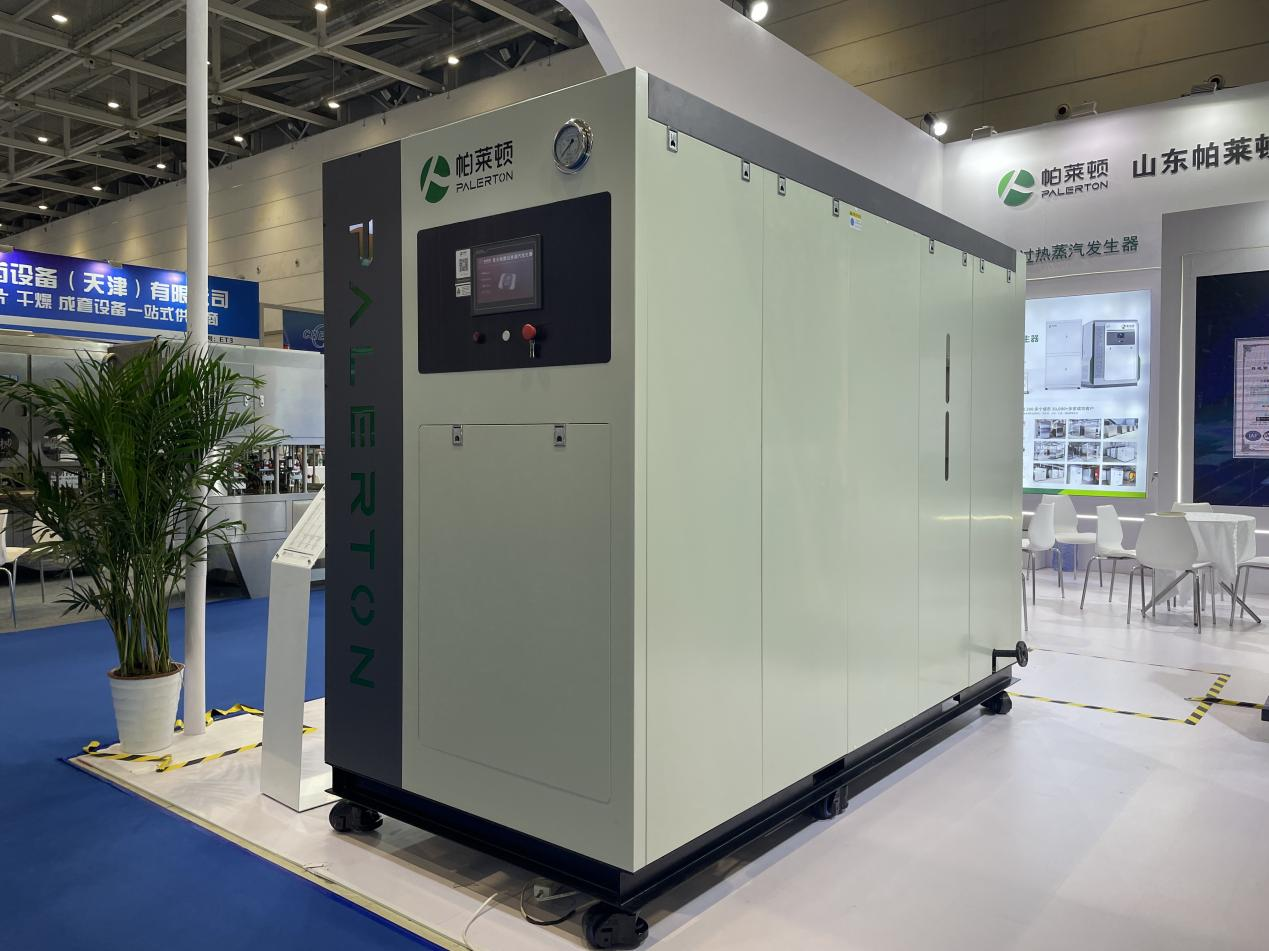

Within the pharmaceutical industry's precision production chain, steam generators serve as invisible “guardians of quality.” The stable steam they provide is the core power source ensuring the smooth execution of critical processes such as sterilization, drying, and distillation. The composite chamber micro-superheated steam generator, with its unique technical design, demonstrates irreplaceable value in meeting the stringent standards of pharmaceutical manufacturing.

In pharmaceutical manufacturing, steam generators play a critical role by supplying stable steam for key processes such as sterilization, drying, and distillation, directly impacting drug quality and production efficiency. The composite chamber superheated steam generator offers numerous advantages to the pharmaceutical industry through its unique design.

Precise temperature and pressure control are paramount. The composite chamber structure maintains steam in a micro-superheated state, keeping temperatures stable within a specific range and minimizing pressure fluctuations. This is particularly significant for processes requiring exacting parameters, such as antibiotic fermentation, ensuring thorough and stable reactions that enhance the concentration of active pharmaceutical ingredients. Additionally, it features high efficiency and energy savings. With a heat exchange efficiency as high as 101.21%, it rapidly generates steam in just 28 seconds, reducing energy consumption. Its compact design saves factory floor space, adapts to the complex production layouts of pharmaceutical companies, lowers production costs, and enhances production efficiency.

Additionally, it features high efficiency and energy savings. With a heat exchange efficiency as high as 101.21%, it rapidly generates steam in just 28 seconds, reducing energy consumption. Its compact design saves factory floor space, adapts to the complex production layouts of pharmaceutical companies, lowers production costs, and enhances production efficiency. From precise temperature and pressure control to outstanding energy efficiency, the composite chamber micro-superheated steam generator comprehensively meets the pharmaceutical industry's multifaceted demands for process stability, safety, and cost-effectiveness. It not only provides reliable steam supply for drug production but also drives the optimization and upgrading of pharmaceutical processes through technological innovation. This makes it a vital enabler for modern pharmaceutical enterprises to enhance their core competitiveness, injecting sustained momentum into the high-quality development of the pharmaceutical sector.

From precise temperature and pressure control to outstanding energy efficiency, the composite chamber micro-superheated steam generator comprehensively meets the pharmaceutical industry's multifaceted demands for process stability, safety, and cost-effectiveness. It not only provides reliable steam supply for drug production but also drives the optimization and upgrading of pharmaceutical processes through technological innovation. This makes it a vital enabler for modern pharmaceutical enterprises to enhance their core competitiveness, injecting sustained momentum into the high-quality development of the pharmaceutical sector.

Related News

What is the purpose of steam generators in the pharmaceutical manufacturing process?

From precise temperature and pressure control to outstanding energy efficiency, the composite chamber micro-superheated steam generator comprehensively meets the pharmaceutical industry's multifaceted demands for process stability, safety, and cost-effectiveness. It not only provides reliable steam supply for drug production but also drives the optimization and upgrading of pharmaceutical processes through technological innovation. This makes it a vital enabler for modern pharmaceutical enterprises to enhance their core competitiveness, injecting sustained momentum into the high-quality development of the pharmaceutical sector.

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.