Can a steam generator be connected to a retort?

The steam generator can be connected to the retort.

The reason why the steam generator can be connected to the autoclave is that the steam generator uses fuel or other energy to heat water to boiling to produce high-temperature and high-pressure steam, which is the main energy source for the autoclave sterilization operation. Its high temperature characteristics of 230°C can destroy the cell structure of microorganisms and achieve efficient sterilization. From the perspective of steam characteristics, steam generators have many advantages over boilers. In terms of thermal efficiency, the composite chamber micro-superheated steam generator adopts a fully premixed condensing design, with a thermal efficiency of up to 101.21% and a comprehensive energy saving rate of 10%-40%. However, the thermal efficiency of steam boilers is around 90%-95%.

From the perspective of steam characteristics, steam generators have many advantages over boilers. In terms of thermal efficiency, the composite chamber micro-superheated steam generator adopts a fully premixed condensing design, with a thermal efficiency of up to 101.21% and a comprehensive energy saving rate of 10%-40%. However, the thermal efficiency of steam boilers is around 90%-95%. In terms of steam generation speed, the composite chamber micro-superheated steam generator performs well, usually producing steam quickly in a short time, 28 seconds to produce steam, and the micro-superheated steam dryness reaches more than 99.07%. However, it often takes longer for the boiler to start and reach a stable steam output state, and the 30-minute preheating at the beginning will consume a lot of fuel, resulting in waste.

In terms of steam generation speed, the composite chamber micro-superheated steam generator performs well, usually producing steam quickly in a short time, 28 seconds to produce steam, and the micro-superheated steam dryness reaches more than 99.07%. However, it often takes longer for the boiler to start and reach a stable steam output state, and the 30-minute preheating at the beginning will consume a lot of fuel, resulting in waste. In terms of safety performance, steam generators have obvious advantages. There is no risk of explosion, and they are equipped with complete safety protection measures such as overheating protection, overpressure protection, and water shortage protection, as well as more than 40 all-round monitoring of the intelligent control system. In contrast, boilers have great safety hazards due to their pressure operation.

In terms of safety performance, steam generators have obvious advantages. There is no risk of explosion, and they are equipped with complete safety protection measures such as overheating protection, overpressure protection, and water shortage protection, as well as more than 40 all-round monitoring of the intelligent control system. In contrast, boilers have great safety hazards due to their pressure operation. In terms of environmental protection, the steam generator uses clean energy, and the nitrogen oxide emission of the composite chamber micro-superheated steam generator is less than 21mg/m³, achieving ultra-low nitrogen emissions, and CO emissions are close to 0, with stepless frequency conversion output to avoid overcapacity. The FGR combustion of the boiler during operation may produce more pollutants such as exhaust gas, which has a greater impact on the environment. It can be seen that the steam generator has become the only choice for connecting the sterilizer with its multi-dimensional steam characteristics.

In terms of environmental protection, the steam generator uses clean energy, and the nitrogen oxide emission of the composite chamber micro-superheated steam generator is less than 21mg/m³, achieving ultra-low nitrogen emissions, and CO emissions are close to 0, with stepless frequency conversion output to avoid overcapacity. The FGR combustion of the boiler during operation may produce more pollutants such as exhaust gas, which has a greater impact on the environment. It can be seen that the steam generator has become the only choice for connecting the sterilizer with its multi-dimensional steam characteristics.

Related News

What are the models of steam generators?

Selecting the appropriate steam generator model requires comprehensive consideration of multiple factors, including the pressure requirements of the application scenario, fuel supply conditions, and steam output capacity. Whether meeting the high-specification demands of large-scale industrial production or providing convenient operation for smaller facilities, suitable models can be found to deliver stable and efficient steam support for production operations across various industries.

What food industries can steam generators be used in?

The composite chamber micro-superheated steam generator plays a vital role in food industry processes such as steaming, sterilization, drying, baking, and puffing. With its high efficiency, energy savings, and precise temperature control, it helps food enterprises enhance product quality and production efficiency.

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.

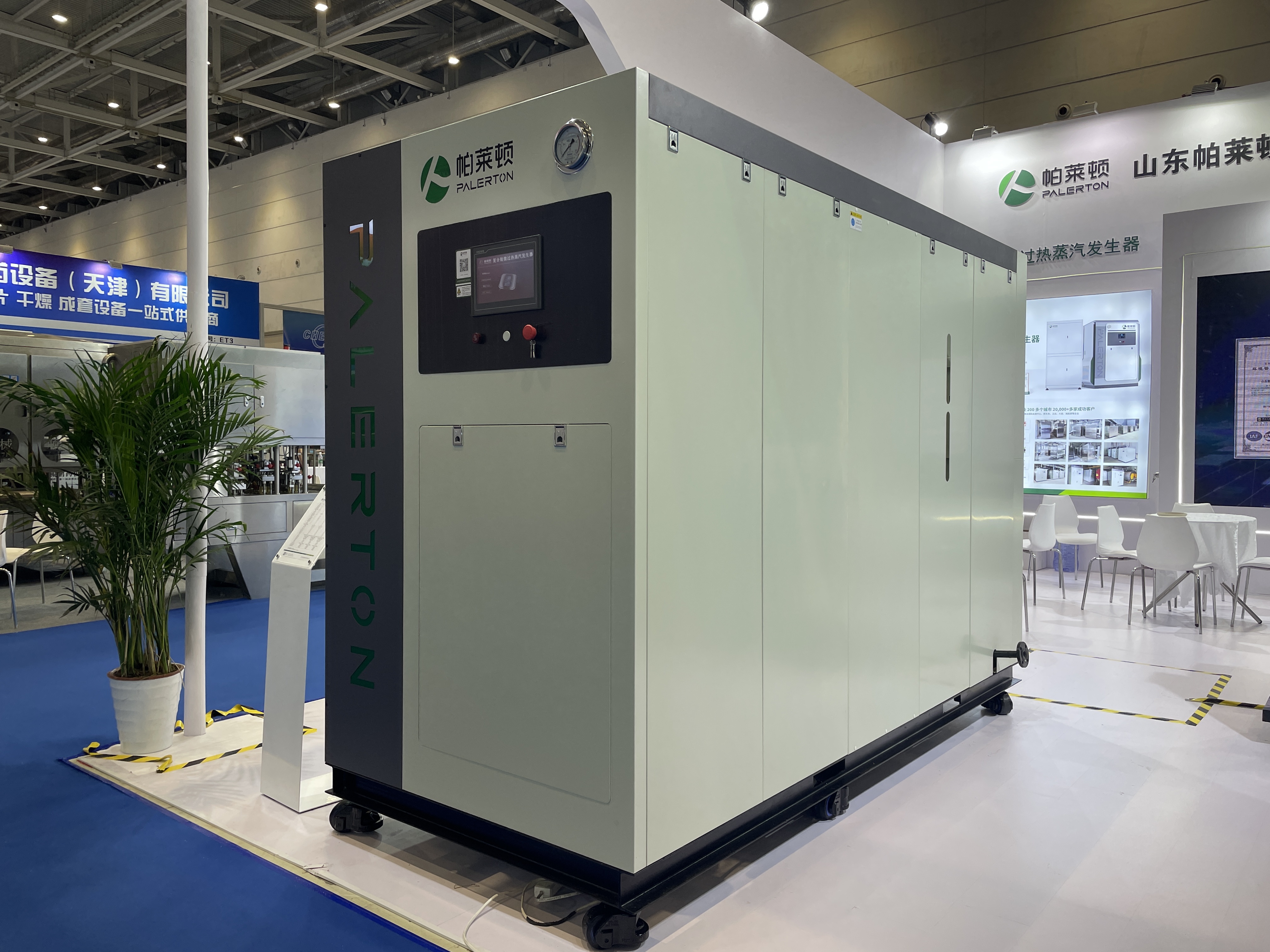

Principle of Composite Chamber Slightly Superheated Steam Generator

This equipment offers significant advantages: no inspection required, no permits needed, and no manual operation. It consumes ≤75m³ of gas per ton of steam produced per hour, with 100% steam dryness, a boiler thermal efficiency of up to 101.21%, and a maximum superheated steam temperature of 230°C. Nitrogen oxide emissions are ≤20mg/m³, while carbon monoxide emissions approach zero. It excels in energy efficiency, environmental protection, safety, and convenience, making it suitable for diverse industrial applications.