What is the gas consumption of the composite cabin micro-superheated steam generator?

The gas consumption of natural gas per steam ton is 75m³/h.

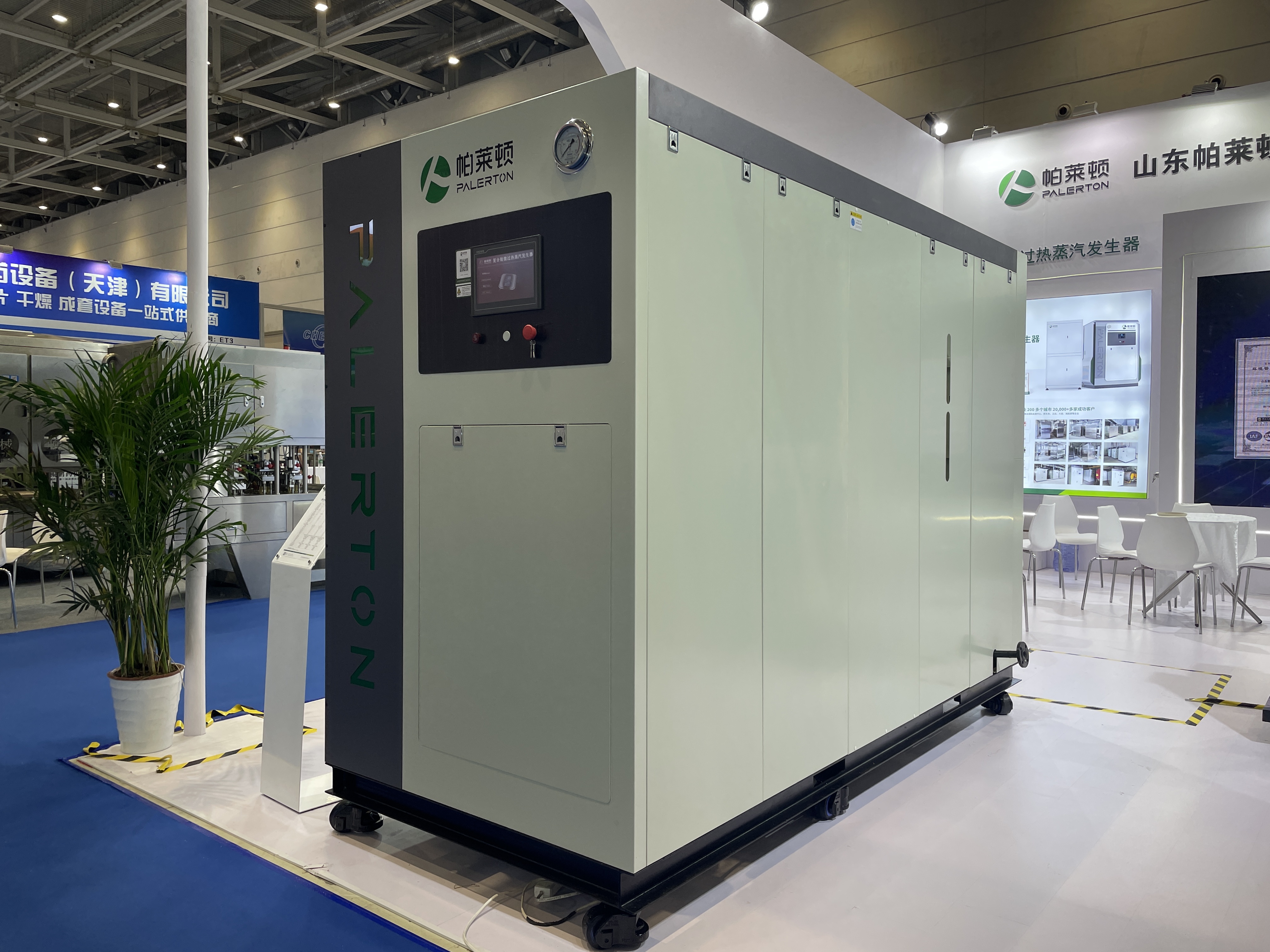

In industrial production, steam generators are important heat supply equipment, and their energy consumption indicators have attracted much attention. The composite chamber micro-superheated steam generator has shown excellent performance in terms of gas consumption, providing strong support for many companies to achieve energy conservation and efficiency improvement.

Low gas consumption brings significant economic benefits to enterprises. The low gas consumption of steam generators has significant advantages in cost control, environmental benefits and equipment performance optimization, bringing multiple positive effects to industrial production.

In terms of economic cost, low gas consumption can directly reduce the energy procurement expenditure of enterprises. Taking the equipment with a gas consumption of 75m³/h per ton of steam as an example, compared with traditional high-energy-consuming models, enterprises can save tens of thousands of yuan in gas costs each year, and long-term operation can significantly increase the profit margin of enterprises. In terms of environmental value, low gas consumption means less fuel combustion. Taking natural gas as an example, for every 10% reduction in gas consumption, nitrogen oxide emissions can be reduced by about 8-12% at the same time. The NOx emissions of the composite chamber micro-superheated steam generator are as low as 21mg/m³, far exceeding the national standard requirements, helping enterprises to easily pass environmental audits and meet the green development needs under the "dual carbon" goal.

In terms of environmental value, low gas consumption means less fuel combustion. Taking natural gas as an example, for every 10% reduction in gas consumption, nitrogen oxide emissions can be reduced by about 8-12% at the same time. The NOx emissions of the composite chamber micro-superheated steam generator are as low as 21mg/m³, far exceeding the national standard requirements, helping enterprises to easily pass environmental audits and meet the green development needs under the "dual carbon" goal. In the wave of industrial energy efficiency upgrade and green transformation, the composite chamber micro-superheated steam generator has become a key link between industrial production and dual carbon goals with its low gas consumption of 75m³/h, thermal efficiency of 101.21% and near-zero CO emissions. Behind this data is the extreme utilization of energy by the equipment, and it is also a firm practice of the industrial field towards the development path of "low consumption, high efficiency, green and sustainable", providing a replicable technical template for energy-saving innovation in more industries.

In the wave of industrial energy efficiency upgrade and green transformation, the composite chamber micro-superheated steam generator has become a key link between industrial production and dual carbon goals with its low gas consumption of 75m³/h, thermal efficiency of 101.21% and near-zero CO emissions. Behind this data is the extreme utilization of energy by the equipment, and it is also a firm practice of the industrial field towards the development path of "low consumption, high efficiency, green and sustainable", providing a replicable technical template for energy-saving innovation in more industries.

Related News

What are the typical applications for steam generators?

Feed Processing: Steam is used for conditioning prior to feed pelleting to soften raw materials and eliminate pathogens such as Salmonella, while facilitating pellet formation. Steam-conditioned feed pellets achieve optimal hardness, resist disintegration, and enhance livestock digestion and absorption rates. In large-scale feed mill production lines, steam generators typically operate in tandem with pelletizers and coolers.

What is the function of a steam generator during wheat drying?

Finally, enhanced adaptability boosts flexibility. The steam generator can flexibly adjust steam output based on wheat moisture content and batch size, accommodating various models of continuous or batch dryers. This meets the diverse needs of both large-scale farming operations and smallholder farmers' decentralized drying requirements, providing stable pre-treatment assurance for grain storage and processing.

The Role of Steam Generators in Preserved Fruit Production

It can be said that steam generators, by providing clean, stable, and controllable thermal energy throughout the entire production process of candied fruits, serve as the core equipment that ensures consistent product quality and enhances production efficiency.

Principle of Composite Chamber Slightly Superheated Steam Generator

This equipment offers significant advantages: no inspection required, no permits needed, and no manual operation. It consumes ≤75m³ of gas per ton of steam produced per hour, with 100% steam dryness, a boiler thermal efficiency of up to 101.21%, and a maximum superheated steam temperature of 230°C. Nitrogen oxide emissions are ≤20mg/m³, while carbon monoxide emissions approach zero. It excels in energy efficiency, environmental protection, safety, and convenience, making it suitable for diverse industrial applications.

What is the gas consumption of the composite cabin micro-superheated steam generator?

In the wave of industrial energy efficiency upgrade and green transformation, the composite chamber micro-superheated steam generator has become a key link between industrial production and dual carbon goals with its low gas consumption of 75m³/h, thermal efficiency of 101.21% and near-zero CO emissions. Behind this data is the extreme utilization of energy by the equipment, and it is also a firm practice of the industrial field towards the development path of "low consumption, high efficiency, green and sustainable", providing a replicable technical template for energy-saving innovation in more industries.

Why can steam generators be used in papermaking?

Therefore, steam generators have been widely used in the papermaking industry with their significant advantages in steam characteristics such as high efficiency, stability, energy saving, and environmental protection, which has effectively promoted the quality improvement, efficiency enhancement, and green development of papermaking production.